Taitou Town Industrial Park, Shouguang City, Shandong Province [email protected]

Elastomer (SBS)/plastic body (APP) modified asphalt waterproof coil is an effective assistant for building waterproofing. SBS or APP modifier - The asphalt is modified with SBS or APP, combining the high elasticity of SBS and good heat resistance of APP. The coil tension strength is big, could adapt the base stretch, waterproof effect is good. Roofing, underground engineering, etc, common construction methods, to provide building waterproof reliable and long-term protection.

Product introduction

PRODUCT DESCRIPTION

SBS modified bitumen waterproof membrane is made by using SBS (styrene butadiene styrene) thermoplastic elastomer modified bitumen as the coating material, high-quality polyester felt, glass fiber felt, and glass fiber reinforced polyester felt as the substrate, fine sand, mineral particles, PE film, aluminum film, and other covering materials, and using specialized mechanical mixing and grinding.

APP modified bitumen waterproof membrane is made from APP (Random Polypropylene), APAO, and APO (Polyolefin Polymer) modified Bitumen as dip coating materials, high-quality polyester felt, glass fiber felt, and substrate, fine sand, mineral particles (sheets), and PE film as covering materials, and refined by advanced technology

PRODUCT FEATURES

·Strong impermeability

·High tensile strength, high elongation, good dimensional stability, strong adaptability to shrinkage deformation and cracking of the base layer,

·Good resistance to high and low temperatures, SBS is suitable for building waterproofing in lower temperature environments, and APP is suitable for building waterproofing in higher temperature environments;

·Good resistance to puncture, tear, corrosion, mold, and weathering,

·Convenient construction, the hot melt method can be operated all year round. and the joints are reliable.

PRODUCT SPECIFICATIONS

·According to physical indicators, it can be divided into two categories: Type l and Type ll;

. According to the reinforcement, it can be divided into three categories: PY, G, and PYG;

.According to the covering materials, it can be divided into four categories: PE film, colored sand, mineral particles, and ALU film;. According to material thickness, it can be divided into 2mm, 3mm, 4mm, 5mm, etc.

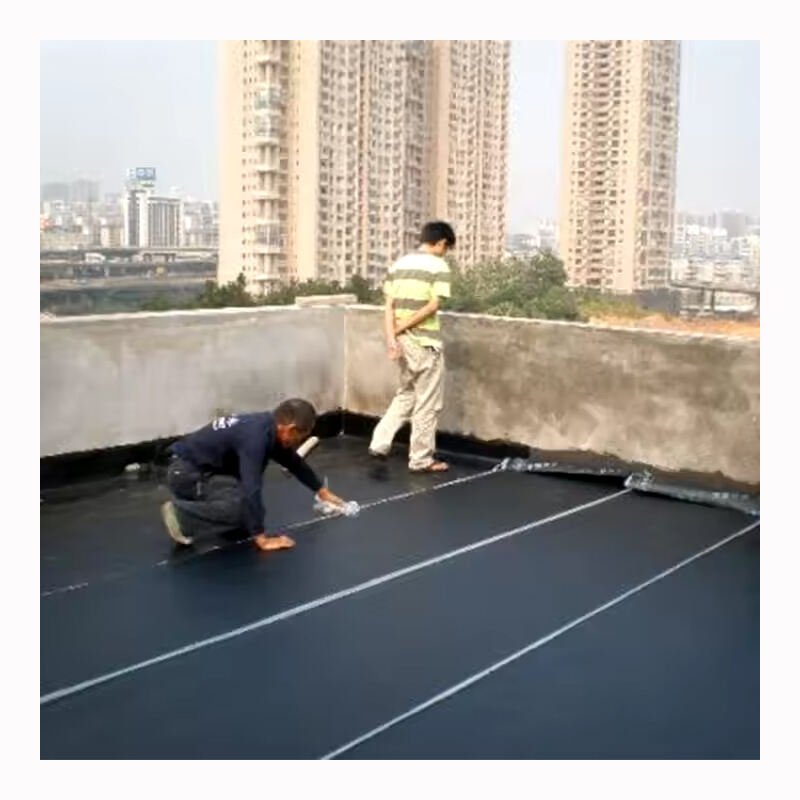

CONSTRUCTION METHOD

Hot melt method, cold adhesion method and cold-hot combination method

the membrane can be constructed alone using the hot melt method or the cold adhesion method, or the cold-hot combination method, i.e., large areas are constructed using the cold adhesion method, and the joint seams are constructed using the hot melt method.

Hot melt method: Use a flame gun or torch to heat the bottom surface of the membrane and the surface of the substrate, so that the bitumen on the surface of the membrane melts. As you heat and roll forward the membrane, use a roller to press it, so that it adheres firmly to the substrate or the membrane.

Cold adhesion method: First, evenly apply the adhesive to the waterproof substrate and the membrane. After slightly drying, you can stick the membrane. Then use a roller to roll it, squeezing out the air below the membrane to make it flat, tight and firmly adhered to the substrate or the membrane.

construction tools and accessories

▪ Construction tools for cleaning the waterproof substrate: shovel, broom, blower, hammer, steel chisel, etc.

▪ Construction tools for laying the membrane: scissors, tape measure, straightedge, scraper, brush, roller.

▪ Special hot melt equipment: single-head or multi-head hot melt gun or torch.

▪ Accessories: substrate treatment agent, membrane adhesive, corner trimming strip.

▪ Before construction, the accepted base should be cleaned and the dust at the corners should be blown away.

▪ Apply primer evenly and consistently, do not apply repeatedly.

▪ After the basic treatment agent is dried, the roof waterproofing project and the underground waterproofing project should be covered with additional layers according to the design requirements.

▪ Determine the order and direction of the rolling material placement and roll the line at the base, and then lay the rolling material. The paste of different parts of the rolling materialshall be carried out according to the following requirements.

▪ Roof: roll and base point paste or strip paste; 800mm around the roof should be fully pasted; The pasting area of the slope roof is more than 70% between the membrane and the membrane;

▪ Basement floor: the membrane and the base can be fully bonded, point bonded, strip bonded or empty, but the membrane and the membrane must be fully bonded;

▪ Basement wall: between the membrane and the base and between the roll and the membrane should be fully pasted;

▪ Additional layer: general parts are fully pasted, deformation joints are allowed to be empty.

▪ Placing order: first high span, then low span; The same height, first far and then close; On the same plane, start at the low point. Direction of roof placement:

▪ Slope <3% parallel to the ridge.

▪ Slope 3%~15% parallel or perpendicular to the ridge.

▪ Slope 15% or vibration should be perpendicular to the ridge direction.

▪ Parallel to the ridge seam in the direction of the water flow, perpendicular to the ridge seam should be laid in the direction of the dominant wind.

Copyright © 2026 Shandong Jinding Waterproof Technology Co., Ltd. All rights reserved. — Privacy Policy