Introduction

Water infiltration remains one of the most persistent challenges across construction, industrial maintenance, and infrastructure management sectors worldwide. Professional contractors, facility managers, and maintenance teams require reliable sealing solutions that deliver immediate results while maintaining long-term durability. The Self Adhesive Non Woven Waterproof Tape Seals Leaks on Concrete Metal Plastic Surfaces Flexible Permanent Water Barrier represents an innovative approach to emergency leak repair and preventive waterproofing applications.

This advanced waterproofing solution combines the convenience of instant application with the reliability of permanent sealing technology. Unlike traditional repair methods that require extensive preparation, curing time, or professional installation, this self-adhesive waterproof barrier provides immediate protection against water penetration across diverse substrate materials. The non-woven construction delivers exceptional conformability while maintaining structural integrity under varying environmental conditions.

Product Overview

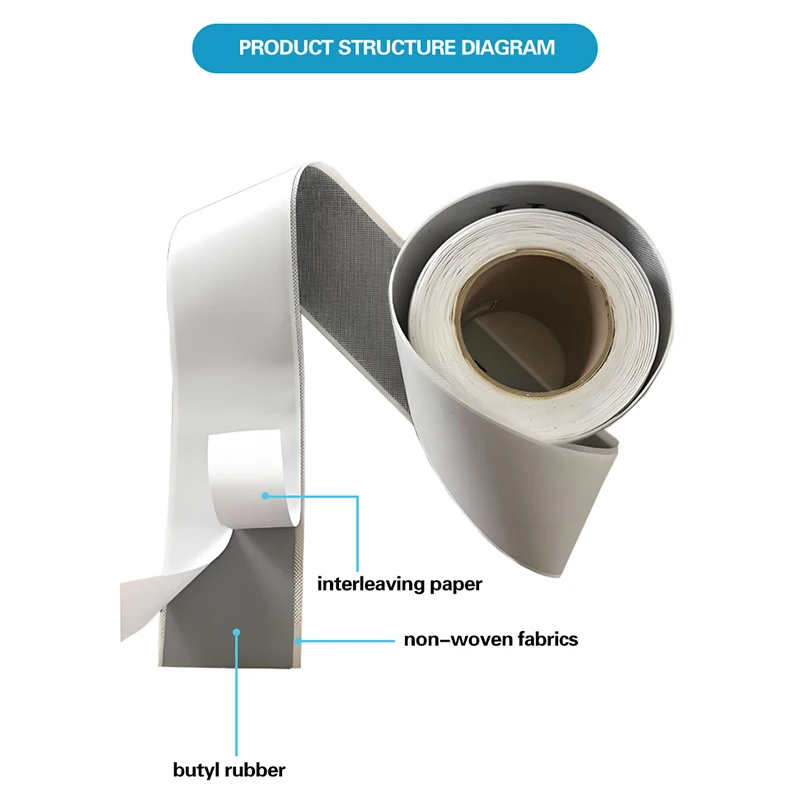

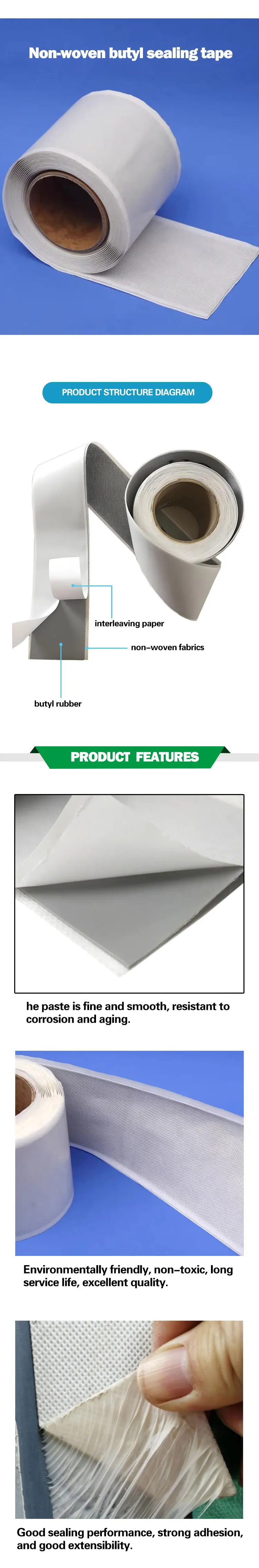

The Self Adhesive Non Woven Waterproof Tape Seals Leaks on Concrete Metal Plastic Surfaces Flexible Permanent Water Barrier features a sophisticated multi-layer construction designed for superior adhesion and waterproofing performance. The specialized non-woven fabric substrate provides excellent flexibility and conformability, allowing the tape to adapt to irregular surfaces, corners, and joint configurations commonly encountered in construction and maintenance applications.

This waterproof sealing tape incorporates advanced adhesive technology that creates immediate bonds with concrete, metal, plastic, and various other building materials without requiring primers or surface preparation beyond basic cleaning. The permanent water barrier characteristics ensure long-lasting protection against moisture intrusion, making it an ideal solution for both emergency repairs and planned waterproofing projects.

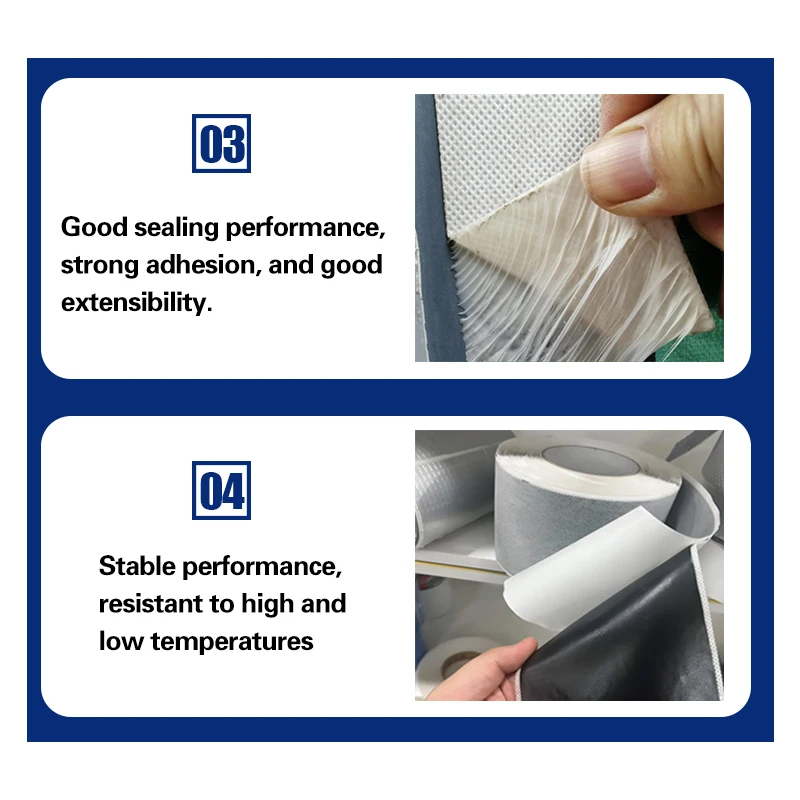

The flexible design accommodates thermal expansion and contraction cycles while maintaining seal integrity, addressing one of the primary failure modes associated with rigid waterproofing systems. This adaptability makes the product particularly valuable for outdoor applications and environments subject to temperature fluctuations throughout seasonal cycles.

Features & Benefits

Advanced Adhesive Technology

The proprietary adhesive formulation creates exceptional bonds across multiple substrate types without compromising removal characteristics when necessary. This balanced approach ensures reliable long-term performance while accommodating future maintenance requirements. The adhesive maintains effectiveness across wide temperature ranges, providing consistent sealing performance in both hot and cold climate conditions.

Superior Conformability

The non-woven construction delivers outstanding flexibility, allowing the waterproof tape to conform to complex geometries, surface irregularities, and three-dimensional configurations. This conformability eliminates the gaps and air pockets that commonly compromise rigid sealing systems, ensuring complete water barrier coverage even on challenging surfaces.

Immediate Protection

Unlike caulks, sealants, or coating systems that require curing time, this self-adhesive waterproof barrier provides instant water protection upon application. This immediate effectiveness proves invaluable during emergency leak situations where delays in achieving water-tight seals can result in significant damage or operational disruption.

Multi-Surface Compatibility

The versatile adhesive system creates reliable bonds with concrete, metal, plastic, glass, and numerous other construction materials commonly encountered in building and infrastructure applications. This broad compatibility reduces inventory requirements while simplifying material selection for maintenance teams managing diverse facility portfolios.

Applications & Use Cases

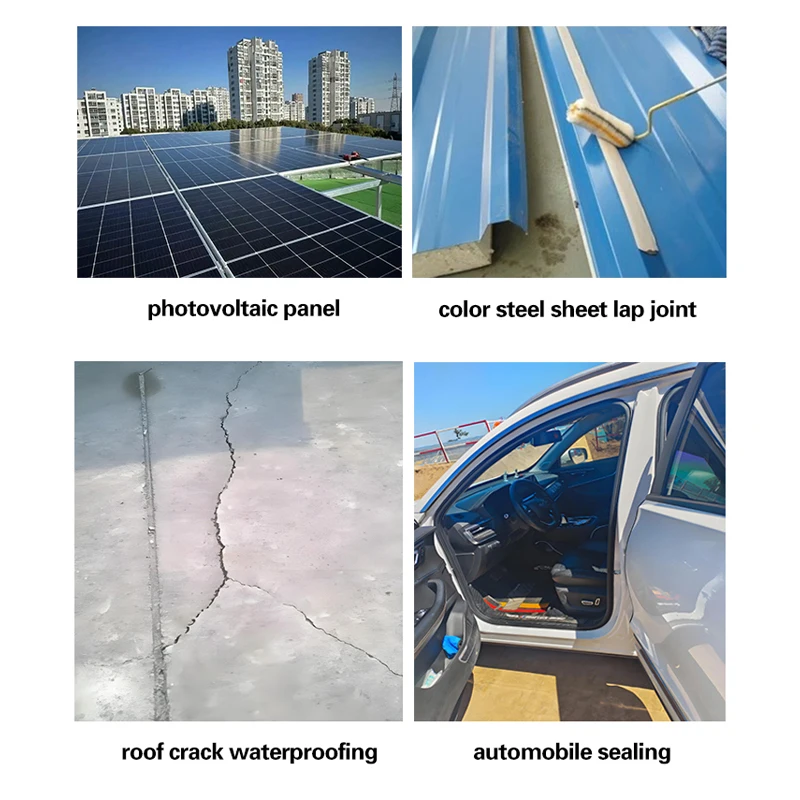

Construction professionals utilize this waterproof sealing solution for foundation waterproofing, basement leak repair, and building envelope sealing applications. The tape's ability to create permanent water barriers on concrete surfaces makes it particularly valuable for below-grade waterproofing where traditional membrane systems may be impractical or cost-prohibitive.

Industrial maintenance teams employ the Self Adhesive Non Woven Waterproof Tape Seals Leaks on Concrete Metal Plastic Surfaces Flexible Permanent Water Barrier for equipment housing protection, pipe penetration sealing, and temporary weatherproofing during facility modifications. The immediate effectiveness and broad substrate compatibility streamline maintenance workflows while ensuring reliable protection against environmental exposure.

Marine and offshore applications benefit from the tape's resistance to moisture and salt exposure, making it suitable for deck sealing, hull repair, and equipment weatherproofing in challenging maritime environments. The flexible permanent water barrier characteristics accommodate the dynamic stresses encountered in marine applications while maintaining seal integrity.

HVAC contractors and building maintenance professionals rely on this waterproof tape for ductwork sealing, roof penetration weatherproofing, and emergency leak containment. The product's ability to seal effectively on both smooth and textured surfaces addresses the diverse sealing challenges encountered in mechanical system installations and building envelope maintenance.

Quality Control & Compliance

Manufacturing processes incorporate comprehensive quality assurance protocols ensuring consistent adhesive performance, dimensional stability, and waterproofing effectiveness across production batches. Raw material specifications maintain strict tolerances for adhesive chemistry, substrate characteristics, and environmental resistance properties essential for reliable field performance.

The Self Adhesive Non Woven Waterproof Tape Seals Leaks on Concrete Metal Plastic Surfaces Flexible Permanent Water Barrier undergoes rigorous testing protocols evaluating adhesion strength, water resistance, temperature cycling performance, and UV stability. These validation procedures ensure product reliability across the diverse environmental conditions encountered in commercial and industrial applications.

International compliance standards guide material selection and manufacturing processes, ensuring compatibility with global construction codes and environmental regulations. This compliance focus facilitates international market acceptance while supporting specifiers' requirements for documented product performance characteristics.

Continuous improvement initiatives incorporate field performance feedback and emerging technology developments to enhance product capabilities and expand application ranges. This commitment to innovation ensures the waterproof sealing tape remains at the forefront of advanced waterproofing technology development.

Customization & Branding Options

Private labeling capabilities accommodate distributor and contractor branding requirements, supporting market differentiation strategies for specialized application niches. Custom packaging options include roll configurations, dispenser compatibility, and protective wrapping systems optimized for specific market segments and distribution channels.

Technical customization services address unique performance requirements including enhanced temperature resistance, specialized adhesive formulations, and modified substrate compatibility characteristics. These engineering capabilities support OEM applications and specialized industrial requirements where standard product specifications may require optimization.

Color coding and identification systems facilitate inventory management and application-specific product selection in multi-product installations. Custom printing capabilities support installation instructions, safety information, and branding requirements while maintaining product integrity and performance characteristics.

Packaging customization extends to retail presentation, bulk contractor packaging, and industrial dispensing systems designed to optimize material utilization and installation efficiency. These options support diverse market channel requirements while maintaining product quality and performance standards.

Packaging & Logistics Support

Protective packaging systems ensure product integrity during international shipping while optimizing container utilization for cost-effective global distribution. Moisture barrier packaging protects adhesive performance characteristics during extended storage periods and varying climatic conditions encountered in international logistics networks.

Bulk packaging options accommodate high-volume users and distribution partners requiring efficient inventory management and dispensing capabilities. These configurations support contractor and industrial user requirements while maintaining individual product protection and identification systems.

International shipping compliance includes documentation support, material safety data sheets, and regulatory compliance certification required for global market access. This comprehensive support streamlines import procedures and facilitates rapid market entry for international distribution partners.

Inventory management support includes demand forecasting assistance, seasonal stocking recommendations, and market-specific product mix optimization based on regional application preferences and regulatory requirements. These services enhance distribution partner success while ensuring adequate product availability.

Why Choose Us

Our organization brings decades of specialized experience in advanced waterproofing technology development and international market distribution, serving diverse industries across global markets. This extensive background ensures deep understanding of application requirements and performance expectations across varied climatic and regulatory environments.

Comprehensive technical support services include application guidance, troubleshooting assistance, and performance optimization consulting to maximize installation success and long-term reliability. Our engineering team collaborates directly with customers to address unique application challenges and develop customized solutions for specialized requirements.

Global supply chain capabilities ensure consistent product availability and reliable delivery scheduling for international distribution partners and high-volume users. Our manufacturing network incorporates redundancy and flexibility to accommodate market demand fluctuations while maintaining quality standards and competitive pricing.

Innovation leadership in waterproof sealing technology development positions our Self Adhesive Non Woven Waterproof Tape Seals Leaks on Concrete Metal Plastic Surfaces Flexible Permanent Water Barrier at the forefront of industry advancement. Continuous research and development investments ensure ongoing product improvement and expansion of application capabilities to address emerging market requirements.

Conclusion

The Self Adhesive Non Woven Waterproof Tape Seals Leaks on Concrete Metal Plastic Surfaces Flexible Permanent Water Barrier represents a significant advancement in waterproofing technology, combining immediate application convenience with long-term reliability across diverse substrate materials. Its innovative design addresses the critical need for versatile sealing solutions that perform consistently across varying environmental conditions and application requirements. The product's comprehensive feature set, including superior conformability, broad substrate compatibility, and permanent water barrier characteristics, positions it as an essential tool for construction professionals, maintenance teams, and industrial users worldwide. Through continuous innovation and commitment to quality excellence, this waterproof sealing solution delivers the performance reliability and application flexibility required for success in today's demanding construction and maintenance environments.