Taitou Town Industrial Park, Shouguang City, Shandong Province [email protected]

Road repair mortar is the main material to ensure the continuous formation of roads. It has fast hardening and strength, recovering road strength in a short time. Tight fit with the existing pavement to ensure that the tensile repair quality does not disstick. The outstanding characteristics of pothole repair conditions can be convenient for construction, can quickly repair potholes, cracks and other diseases, extend the service life of the road, reduce maintenance costs.

Product introduction

PRODUCT DESCRIPTION

road repair mortar is a high-performance material specially used to repair concrete surfaces such as roads, bridges and parking lots. The mortar has excellent bond strength, durability and crack resistance, and is suitable for road repair under various climatic conditions.

PRODUCT FEATURES

▪ high strength: The material achieves high strength quickly, ensuring the bearing capacity of the repair site.

▪ wear resistance: It has good wear resistance, making it suitable for high-traffic areas.

▪ crack resistance: The material offers superior crack resistance, which helps reduce later maintenance costs.

▪ quick drying: It cures quickly, shortening construction time.

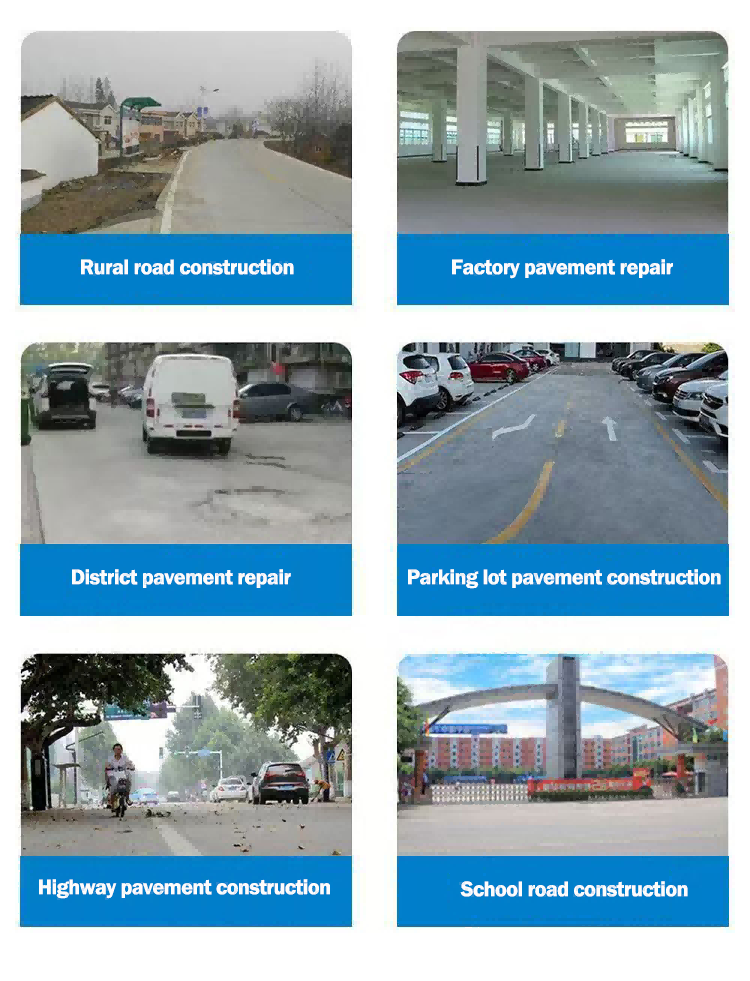

SCOPE OF APPLICATION

Repair of cracks and potholes in concrete roads and Bridges

▪ Maintenance of parking lot and factory floor

▪ Repair of sidewalks and footpaths

▪ Repair of other concrete structures

MATTERS NEEDING ATTENTION

1. During construction, please wear protective gloves and masks to avoid direct contact with skin.

2. Road repair mortar should be used at an ambient temperature of 5°C to 35°C to avoid construction in rainy or extreme weather.

3. Please read the detailed instructions and safety data sheet on the product packaging carefully before starting to use.

4. Store unused mortar in a cool, dry place, away from moisture and direct sunlight. it is recommended to use as soon as possible after opening.

5. Packing specifications. According to different products, the packing specifications may be different, please refer to the packing information of

the specific product.

CONSTRUCTION METHOD

1.surface treatment.

Remove loose objects, dust and oil from the repaired area to ensure that the surface is clean. For larger cracks or defects, it is recommended to

expand the repair area to ensure good bonding.

2.stir.

prepare clean water according to the water to ash ratio recommended in the product manual.

Mix the road repair mortar with water in proportion, and use a blender to

mix evenly until there are no dry powder particles.

3.Construction.

Apply the evenly mixed mortar to the repaired area and level it with a tool such as a spatula.

According to the need, surface texture treatment can be carried out to

improve the anti-slip performance of the road surface.

4.Care.

Proper curing is necessary after repair, which involves keeping the surface wet. It is recommended that the curing time beat least 48 hours to ensure that the mortar is fully cured.

Copyright © 2026 Shandong Jinding Waterproof Technology Co., Ltd. All rights reserved. — Privacy Policy