butyl tape manufacturers

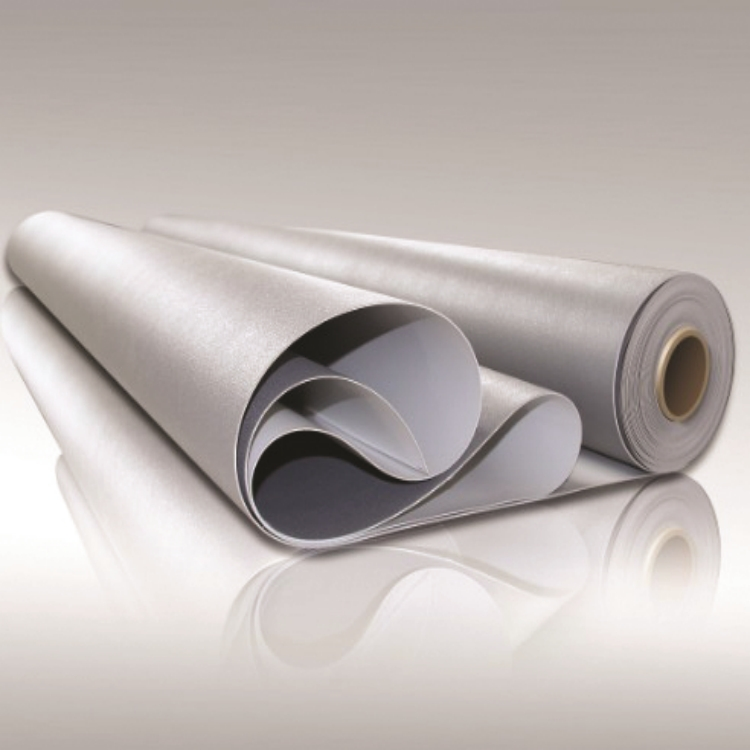

Butyl tape manufacturers stand at the forefront of industrial sealing solutions, producing high-quality adhesive products that serve multiple sectors. These manufacturers combine advanced polymer technology with precise manufacturing processes to create tapes that offer superior moisture resistance and durability. Their production facilities utilize state-of-the-art equipment to ensure consistent quality and adherence to international standards. The manufacturing process involves careful selection of raw materials, including butyl rubber compounds and specialized adhesive formulations, which are engineered to provide excellent adhesion across various surfaces. These manufacturers implement rigorous quality control measures throughout the production cycle, from raw material testing to final product inspection. Their facilities are equipped with modern research and development laboratories where new formulations are tested and existing products are enhanced to meet evolving market demands. The products they create find applications in construction, automotive, aerospace, and marine industries, offering solutions for weatherproofing, insulation, and vapor sealing. These manufacturers also provide customized solutions, allowing customers to specify tape width, thickness, and adhesive properties according to their specific requirements.