When it comes to protecting basements and wet areas from moisture infiltration, waterproof mortar has become an essential construction material. This specialized mortar provides superior moisture resistance compared to standard cement mixtures, making it particularly valuable in below-grade applications. Understanding the properties and applications of waterproof mortar is crucial for contractors, architects, and property owners who need reliable moisture protection in challenging environments.

Basement construction presents unique challenges due to constant exposure to groundwater, soil moisture, and hydrostatic pressure. Traditional mortar materials often fail in these conditions, leading to water penetration, structural damage, and costly repairs. The implementation of high-quality waterproof mortar systems addresses these concerns while providing long-term durability and performance in moisture-prone environments.

Understanding Waterproof Mortar Properties

Chemical Composition and Moisture Resistance

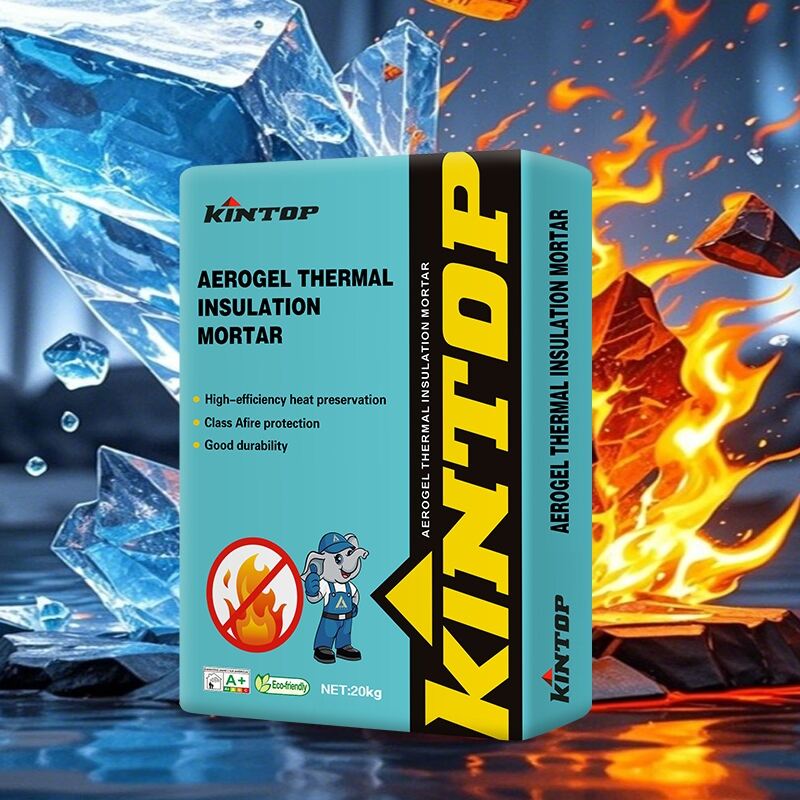

Waterproof mortar contains specialized additives that create a hydrophobic barrier within the cured material. These chemical admixtures modify the pore structure of the mortar, reducing permeability and preventing water molecules from penetrating through capillary action. The polymer-modified formulations used in modern waterproof mortar provide enhanced flexibility and crack resistance, which are critical factors in basement applications where structural movement is common.

The waterproofing mechanism relies on integral crystalline technology or polymer modification that blocks water pathways while maintaining vapor permeability. This balance ensures that moisture cannot penetrate from the exterior while allowing interior humidity to escape, preventing trapped moisture problems that can lead to mold growth and structural deterioration.

Performance Characteristics in Wet Environments

Professional-grade waterproof mortar demonstrates exceptional performance under hydrostatic pressure conditions commonly found in basement environments. The material maintains structural integrity while resisting water penetration up to significant pressure levels, making it suitable for both interior and exterior basement wall applications. This pressure resistance is particularly important in areas with high water tables or during periods of heavy rainfall.

The durability of waterproof mortar extends beyond simple moisture resistance to include freeze-thaw stability, chemical resistance, and long-term adhesion properties. These characteristics ensure that basement waterproofing systems remain effective throughout their intended service life, even under challenging environmental conditions.

Basement Application Techniques

Surface Preparation and Installation Methods

Proper surface preparation is fundamental to waterproof mortar performance in basement applications. The substrate must be clean, sound, and free from contaminants that could compromise adhesion. This includes removing any existing coatings, efflorescence, or loose material that might interfere with the bond between the waterproof mortar and the concrete substrate.

Installation techniques for waterproof mortar vary depending on the specific product formulation and application requirements. Spray application methods provide uniform coverage and excellent penetration into substrate pores, while trowel application offers precise control for detailed work around penetrations and corners. The choice of application method significantly impacts the final performance and longevity of the waterproofing system.

Thickness Requirements and Coverage Considerations

The optimal thickness for waterproof mortar applications depends on the specific exposure conditions and performance requirements. Basement walls typically require minimum thickness specifications to ensure adequate moisture protection while maintaining structural compatibility with the existing substrate. Thicker applications provide enhanced durability but may require modified mixing and application procedures.

Coverage calculations must account for substrate texture, porosity, and surface irregularities that can significantly impact material consumption. Professional contractors experienced with waterproof mortar applications understand these variables and can accurately estimate material requirements while ensuring complete coverage of all critical areas.

Wet Area Performance Evaluation

Hydrostatic Pressure Resistance

Waterproof mortar systems undergo rigorous testing to establish their resistance to hydrostatic pressure in wet area applications. These tests simulate real-world conditions where groundwater or surface water creates pressure against basement walls and other below-grade structures. The ability to withstand these pressures without leakage is a critical performance characteristic that distinguishes high-quality waterproof mortar from conventional materials.

Testing protocols evaluate both positive and negative side pressure resistance, as basement applications may encounter water pressure from either direction depending on site conditions and drainage systems. The superior pressure resistance of modern waterproof mortar formulations provides reliable protection even in challenging installations where traditional waterproofing methods might fail.

Long-Term Durability Assessment

Long-term performance evaluation of waterproof mortar in wet environments involves accelerated aging tests that simulate years of exposure to moisture, temperature cycles, and chemical exposure. These assessments demonstrate the material's ability to maintain its waterproofing properties over extended periods, which is essential for basement applications where access for maintenance or repairs is limited.

Field performance data from completed projects provides valuable insights into the real-world durability of waterproof mortar systems. This information helps engineers and contractors make informed decisions about material selection and application methods for specific basement waterproofing requirements.

Comparative Analysis with Alternative Solutions

Membrane Systems versus Mortar Applications

Traditional membrane waterproofing systems offer different advantages and limitations compared to waterproof mortar applications in basement environments. While membranes provide excellent water resistance, they require careful installation and are vulnerable to punctures or tears that can compromise the entire system. Waterproof mortar offers a monolithic barrier that eliminates seam-related failure points while providing structural reinforcement.

The installation complexity and cost considerations differ significantly between membrane and waterproof mortar systems. Mortar applications typically require less specialized labor and equipment while providing comparable or superior long-term performance in many basement applications. This makes waterproof mortar an attractive option for both new construction and retrofit waterproofing projects.

Coating Systems and Surface Treatments

Surface-applied waterproof coatings represent another alternative to integral waterproof mortar systems in basement applications. These coatings offer easy application but may lack the structural integrity and longevity of mortar-based solutions. The penetrating nature of waterproof mortar provides deeper protection that becomes integral to the substrate structure.

Performance comparisons between coating systems and waterproof mortar reveal distinct advantages for mortar applications in high-exposure environments. The structural contribution of waterproof mortar adds value beyond simple moisture protection, making it particularly suitable for basement walls that must resist both water infiltration and structural loads.

Installation Best Practices

Quality Control and Testing Procedures

Successful waterproof mortar installations require comprehensive quality control procedures that begin with material verification and continue through final acceptance testing. This includes confirming that the delivered waterproof mortar meets specification requirements and maintaining proper storage conditions to preserve material properties prior to application.

Field testing procedures for waterproof mortar installations typically include adhesion testing, thickness verification, and water penetration resistance evaluation. These tests provide objective verification that the installed system meets performance requirements and will provide reliable long-term protection for basement and wet area applications.

Environmental Conditions and Timing

Environmental conditions during waterproof mortar installation significantly impact final performance and durability. Temperature, humidity, and substrate moisture content must be controlled within specified ranges to ensure proper curing and development of waterproofing properties. This is particularly important in basement environments where conditions may vary significantly from exterior applications.

Project scheduling considerations for waterproof mortar installations must account for curing time requirements and protection from premature water exposure. Proper planning ensures that the material achieves full strength and waterproofing performance before being subjected to service conditions in basement and wet area applications.

Maintenance and Longevity Considerations

Inspection and Monitoring Protocols

Regular inspection of waterproof mortar installations helps identify potential issues before they develop into significant problems. Visual inspection techniques can detect surface changes, cracking, or other indicators that may suggest maintenance requirements. Early detection and prompt repair of minor issues help preserve the long-term effectiveness of basement waterproofing systems.

Monitoring protocols for waterproof mortar systems may include moisture detection measurements and structural assessment to ensure continued performance. These evaluations provide valuable data about system condition and help predict maintenance requirements, allowing property owners to plan for necessary repairs or upgrades.

Repair and Restoration Methods

When repairs are necessary, waterproof mortar systems typically offer straightforward restoration procedures that maintain system integrity. Small cracks or damaged areas can often be repaired using compatible materials and techniques that restore full waterproofing performance. This repairability is a significant advantage over membrane systems that may require complete replacement when damaged.

The compatibility of repair materials with existing waterproof mortar installations is crucial for maintaining long-term performance. Using materials with similar properties and expansion characteristics ensures that repairs integrate properly with the existing system and do not create weak points that could compromise overall waterproofing effectiveness.

FAQ

How long does waterproof mortar last in basement applications

High-quality waterproof mortar systems typically provide 20-30 years of reliable service in basement applications when properly installed and maintained. The actual service life depends on factors such as exposure conditions, substrate quality, and installation workmanship. Regular inspection and minor maintenance can extend this service life significantly.

Can waterproof mortar be applied to existing basement walls

Yes, waterproof mortar can be successfully applied to existing basement walls as a retrofit waterproofing solution. The key requirements are proper surface preparation, structural soundness of the existing wall, and selection of appropriate waterproof mortar formulations compatible with the substrate material.

What is the difference between waterproof mortar and regular mortar

Waterproof mortar contains specialized additives such as integral crystalline admixtures or polymer modifications that create hydrophobic properties and reduce permeability. Regular mortar lacks these waterproofing components and is susceptible to water penetration through capillary action and pore structure.

Is professional installation required for waterproof mortar applications

While some waterproof mortar products are designed for DIY application, professional installation is recommended for critical basement waterproofing applications. Experienced contractors understand proper surface preparation, mixing procedures, application techniques, and quality control measures necessary for optimal long-term performance.