Building longevity remains a critical concern for property developers, contractors, and homeowners worldwide. The structural integrity of industrial facilities and residential properties depends heavily on the quality of materials used during construction. Among the most effective solutions for enhancing durability is the implementation of specialized waterproof mortar systems that create robust barriers against moisture infiltration and environmental damage.

Modern construction demands materials that can withstand extreme weather conditions, temperature fluctuations, and continuous exposure to moisture. Traditional cement-based products often fall short when faced with these challenges, leading to premature deterioration and costly repairs. The integration of advanced polymer powder additives and specialized cement formulations has revolutionized how buildings resist water damage and maintain structural soundness over decades.

Understanding Waterproof Mortar Technology

Core Components and Composition

Contemporary waterproof mortar systems incorporate sophisticated polymer powder additives that fundamentally alter the binding characteristics of standard cement mixtures. These additives create microscopic barriers within the mortar matrix, preventing water molecules from penetrating the structure while maintaining necessary breathability for moisture vapor transmission. The chemical bonding process between portland cement and polymer compounds results in enhanced flexibility and crack resistance.

The composition typically includes high-grade cement, specially treated sand aggregates, waterproofing agents, and reinforcement fibers. Each component serves a specific function in creating a cohesive system that outperforms traditional mortar applications. The polymer integration occurs at the molecular level, forming cross-linked networks that maintain integrity even under stress conditions.

Mechanical Properties and Performance Characteristics

Advanced waterproof mortar demonstrates superior adhesion strength compared to conventional alternatives, often achieving bond strengths exceeding 2.5 MPa in laboratory testing. This enhanced bonding capacity translates to reduced risk of delamination and improved long-term performance in both horizontal and vertical applications. The material exhibits excellent workability during application while maintaining consistent performance across varying temperature ranges.

Flexural strength improvements of 40-60% over standard mortar formulations provide additional resistance to thermal expansion and contraction cycles. This characteristic proves particularly valuable in regions experiencing significant temperature variations throughout the year. The enhanced flexibility prevents the formation of hairline cracks that typically serve as entry points for water infiltration.

Industrial Applications and Benefits

Manufacturing Facility Protection

Industrial environments present unique challenges for building envelope protection, including exposure to chemical vapors, high humidity levels, and mechanical stress from heavy equipment operations. Waterproof mortar systems provide comprehensive protection for concrete floors, wall surfaces, and structural joints in manufacturing facilities. The chemical resistance properties prevent deterioration from industrial cleaning agents and process-related contamination.

Food processing plants, pharmaceutical manufacturing facilities, and chemical production sites particularly benefit from the antimicrobial properties inherent in properly formulated waterproof mortar. The non-porous surface finish inhibits bacterial growth while facilitating thorough cleaning and sanitization procedures required by regulatory standards. This dual functionality reduces maintenance costs while ensuring compliance with health and safety requirements.

Infrastructure and Commercial Construction

Large-scale infrastructure projects including bridges, tunnels, and commercial buildings require materials capable of withstanding decades of environmental exposure without significant degradation. Waterproof mortar applications in these contexts focus on joint sealing, crack repair, and protective coating systems that extend service life while minimizing maintenance interventions.

The economic benefits become apparent when considering the lifecycle costs associated with building maintenance and renovation. Structures protected with high-quality waterproof mortar systems typically require 50-70% fewer repair interventions over a 20-year period compared to those using conventional materials. This reduction in maintenance frequency translates to significant cost savings and reduced operational disruptions.

Residential Building Applications

Foundation and Basement Waterproofing

Residential foundation systems face constant exposure to groundwater, soil moisture, and hydrostatic pressure that can compromise structural integrity over time. Waterproof mortar applications in basement construction create effective moisture barriers that prevent water infiltration while allowing proper drainage around foundation elements. The material bonds exceptionally well to concrete block, poured concrete, and masonry substrates commonly used in residential construction.

Below-grade applications require materials that maintain performance under continuous moisture exposure and varying soil conditions. Properly applied waterproof mortar systems resist freeze-thaw damage, root penetration, and chemical attack from soil-based contaminants. The flexibility characteristics accommodate minor foundation settling without creating vulnerable crack formations.

Exterior Wall Systems and Weather Protection

Residential exterior walls require protection from wind-driven rain, snow infiltration, and ultraviolet radiation exposure. Waterproof mortar serves as an excellent substrate for exterior insulation systems while providing primary weather protection for underlying structural elements. The material accepts a wide range of finish coatings including stucco, elastomeric paints, and architectural coatings.

Window and door installations benefit significantly from waterproof mortar applications around rough openings and penetration points. The material creates seamless transitions between different building components while maintaining consistent thermal performance. This attention to detail prevents the formation of thermal bridges and moisture accumulation points that frequently lead to premature deterioration.

Installation Techniques and Best Practices

Surface Preparation and Substrate Requirements

Successful waterproof mortar installation begins with thorough substrate preparation including removal of loose material, dust, and contaminants that could interfere with proper bonding. Concrete surfaces require mechanical abrasion or chemical etching to create adequate surface profile for optimal adhesion. Moisture content levels must be controlled within manufacturer specifications to prevent bonding failures and premature curing issues.

Temperature and humidity conditions during application significantly impact final performance characteristics. Installation during extreme weather conditions requires additional precautions including temporary climate control and extended curing periods. Professional contractors typically recommend installation temperatures between 40-90°F with relative humidity levels below 85% for optimal results.

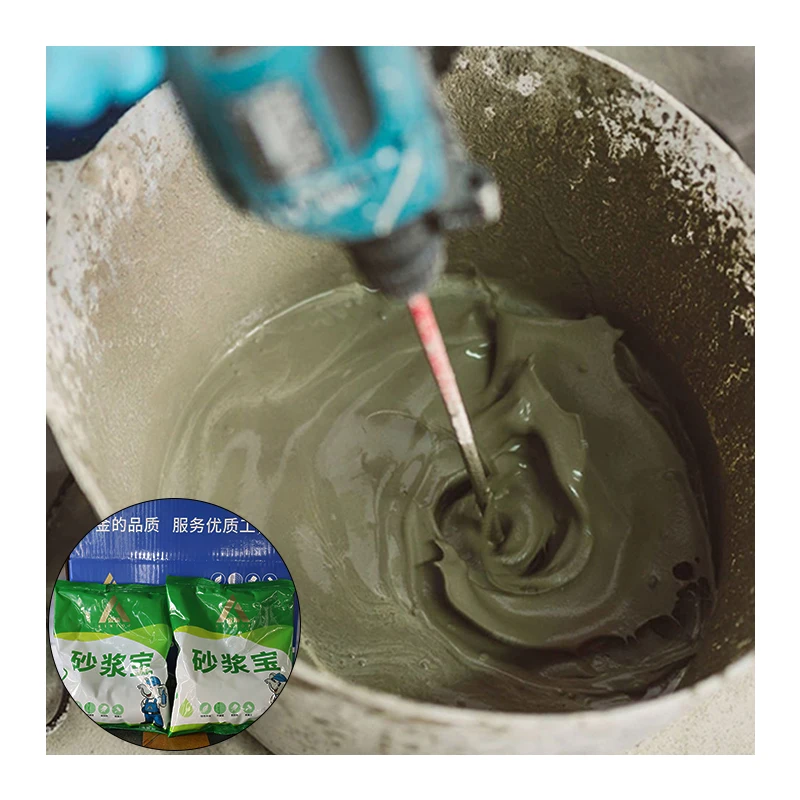

Mixing and Application Methods

Proper mixing procedures ensure uniform distribution of polymer additives and achieve specified performance characteristics. Mechanical mixing equipment provides consistent results while preventing the formation of lumps or unmixed portions that could compromise waterproofing effectiveness. The mixing time typically ranges from 3-5 minutes depending on batch size and equipment specifications.

Application thickness varies according to specific project requirements but generally ranges from 3-10mm for most waterproofing applications. Multiple thin coats often provide superior performance compared to single thick applications, allowing better substrate penetration and reduced risk of shrinkage cracking. Each coat requires proper curing before subsequent applications to ensure optimal inter-coat adhesion.

Long-Term Performance and Maintenance

Durability Assessment and Service Life

Field performance data from installations dating back over two decades demonstrates the exceptional longevity of properly applied waterproof mortar systems. Regular inspections reveal minimal degradation even in harsh environmental conditions including coastal salt exposure, freeze-thaw cycles, and industrial atmospheric contamination. The polymer-modified chemistry maintains flexibility and adhesion properties well beyond the design service life of many conventional materials.

Accelerated aging tests simulate 25-50 years of natural exposure in laboratory conditions, providing valuable insights into long-term performance expectations. Results consistently show retention of critical properties including bond strength, waterproofing effectiveness, and crack resistance throughout extended exposure periods. This performance predictability allows accurate lifecycle cost calculations for project planning purposes.

Maintenance Requirements and Inspection Protocols

Routine maintenance of waterproof mortar installations involves periodic visual inspections and minor repairs as needed. Unlike traditional systems that require frequent reapplication or major restoration work, polymer-modified waterproof mortar typically requires only occasional cleaning and spot repairs of damaged areas. The self-healing properties of some formulations actually improve performance over time as polymer networks continue to develop.

Professional inspection protocols recommend annual visual assessments with detailed documentation of any observed changes or potential issues. Early identification of minor problems allows cost-effective repairs that prevent more extensive damage and maintain system integrity. The inspection process typically requires minimal specialized equipment and can be performed by qualified maintenance personnel.

FAQ

What makes waterproof mortar more effective than traditional cement-based products?

Waterproof mortar incorporates advanced polymer additives that create microscopic barriers within the cement matrix, preventing water penetration while maintaining breathability. These chemical modifications result in 40-60% greater flexural strength and superior crack resistance compared to conventional mortar. The enhanced bonding characteristics and self-sealing properties provide long-term protection that traditional materials cannot match.

How long does waterproof mortar typically last in harsh environmental conditions?

Properly applied waterproof mortar systems demonstrate service lives exceeding 20-25 years even in challenging environments including coastal areas, industrial facilities, and regions with extreme temperature fluctuations. Field performance data shows minimal degradation after two decades of exposure, with many installations maintaining original performance characteristics. The polymer-modified chemistry provides exceptional resistance to freeze-thaw damage, chemical attack, and mechanical stress.

Can waterproof mortar be applied over existing concrete or masonry surfaces?

Yes, waterproof mortar bonds excellently to properly prepared concrete, masonry, and other cementitious substrates. Surface preparation requirements include removal of loose material, contaminants, and creation of adequate surface profile through mechanical abrasion or chemical etching. Existing coatings or sealers must be completely removed to ensure proper adhesion. Moisture content and temperature conditions must be controlled within manufacturer specifications during application.

What are the key factors that determine waterproof mortar application success?

Success depends on proper substrate preparation, environmental conditions during application, mixing procedures, and curing protocols. Surface preparation must create adequate bond profile while removing contaminants that could interfere with adhesion. Application temperature between 40-90°F and relative humidity below 85% provide optimal conditions. Proper mixing ensures uniform polymer distribution, while controlled curing prevents premature moisture loss that could compromise final performance characteristics.

Table of Contents

- Understanding Waterproof Mortar Technology

- Industrial Applications and Benefits

- Residential Building Applications

- Installation Techniques and Best Practices

- Long-Term Performance and Maintenance

-

FAQ

- What makes waterproof mortar more effective than traditional cement-based products?

- How long does waterproof mortar typically last in harsh environmental conditions?

- Can waterproof mortar be applied over existing concrete or masonry surfaces?

- What are the key factors that determine waterproof mortar application success?