Construction professionals and DIY enthusiasts constantly seek reliable sealing solutions that deliver exceptional performance across diverse applications. Among the numerous adhesive options available in today's market, butyl tape has emerged as a premium choice for creating watertight, airtight, and durable seals. This specialized sealing material combines advanced polymer chemistry with practical engineering design to address the most challenging sealing requirements in construction, automotive, and industrial environments.

The unique composition of butyl tape makes it particularly effective for long-term sealing applications where traditional materials often fail. Unlike standard adhesive tapes that may deteriorate under environmental stress, butyl tape maintains its flexibility and adhesive properties for years, even when exposed to extreme temperature fluctuations, moisture, and UV radiation. This remarkable durability stems from the inherent characteristics of butyl rubber, which forms the foundation of this advanced sealing technology.

Understanding Butyl Tape Composition and Structure

Butyl Rubber Foundation Technology

The effectiveness of butyl tape begins with its primary component: butyl rubber, a synthetic elastomer known for exceptional impermeability to gases and moisture. This specialized rubber compound exhibits low gas permeability rates, making it ideal for creating barriers against air and water infiltration. The molecular structure of butyl rubber allows it to maintain elasticity across a wide temperature range while providing superior chemical resistance compared to natural rubber alternatives.

Manufacturing processes for high-quality butyl tape involve careful selection of butyl rubber grades optimized for specific applications. The rubber undergoes precise vulcanization to achieve the desired balance of flexibility and durability. Advanced formulations incorporate stabilizers and antioxidants that protect the material from environmental degradation, ensuring consistent performance throughout its service life.

Adhesive System Engineering

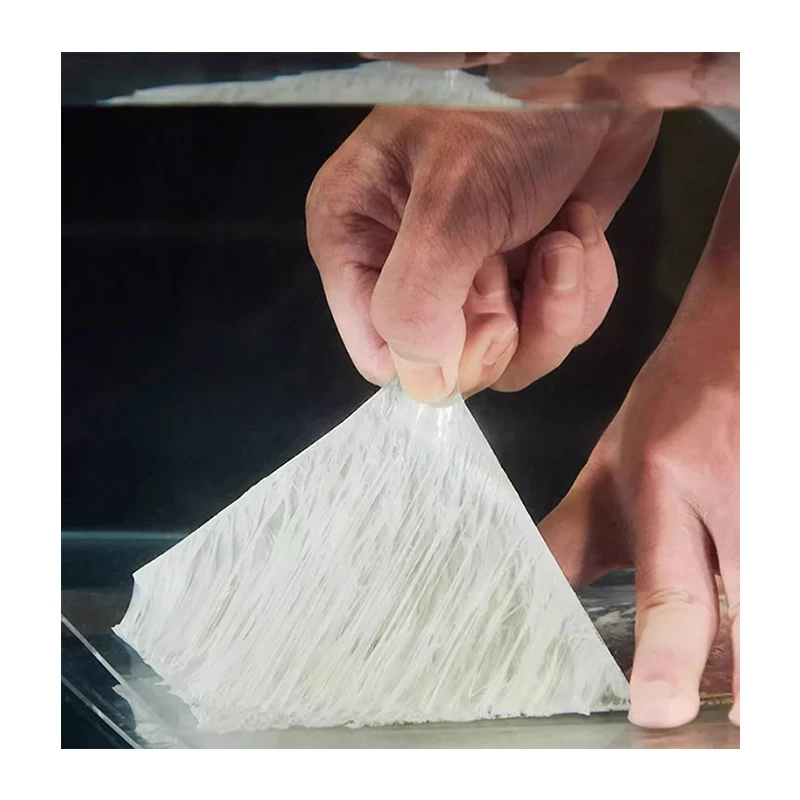

The adhesive layer in professional-grade butyl tape utilizes specialized tackifying resins that create immediate bond formation upon contact with substrates. These pressure-sensitive adhesive systems are engineered to flow into surface irregularities, creating intimate contact that enhances seal integrity. The adhesive chemistry is designed to maintain tackiness over time while resisting cold flow that could compromise the seal's dimensional stability.

Reinforcement materials, such as aluminum foil or polyester films, are often integrated into butyl tape constructions to provide dimensional stability and enhanced barrier properties. The butyl tape with aluminum foil backing offers superior puncture resistance and reflective properties that contribute to thermal management in building envelope applications.

Performance Characteristics in Sealing Applications

Waterproofing and Moisture Control

The waterproofing capabilities of butyl tape exceed those of conventional sealing materials due to its non-porous structure and excellent conformability. When properly applied, butyl tape creates a continuous moisture barrier that prevents water penetration even under hydrostatic pressure conditions. The material's ability to self-seal around penetrating fasteners adds another layer of protection against water intrusion.

Long-term waterproofing performance relies on the tape's resistance to water absorption and its maintained flexibility over years of service. Laboratory testing demonstrates that quality butyl tape maintains its waterproofing properties after thousands of thermal cycles, making it suitable for exterior applications where temperature variations are significant. The tape's conformability allows it to accommodate substrate movement without compromising the seal integrity.

Temperature Performance and Durability

Superior butyl tape formulations maintain their sealing effectiveness across temperature ranges from -40°F to 200°F, covering the environmental conditions encountered in most construction applications. The material's low-temperature flexibility prevents cracking and loss of adhesion in cold climates, while its high-temperature stability prevents softening and flow in hot conditions.

Thermal cycling tests reveal that butyl tape maintains consistent adhesion and barrier properties through repeated expansion and contraction cycles. This thermal stability is crucial for roofing applications where daily temperature swings create significant stress on sealing materials. The tape's ability to recover from deformation ensures that temporary substrate movement does not create permanent seal failure.

Application Methodologies for Maximum Effectiveness

Surface Preparation Requirements

Achieving optimal performance from butyl tape requires proper surface preparation that ensures maximum adhesive contact and long-term bond durability. Surfaces must be clean, dry, and free from oils, dust, or loose particles that could interfere with adhesion. For porous substrates, primer application may be necessary to create a suitable bonding surface and prevent adhesive migration.

Temperature considerations during application significantly impact the final seal quality. Butyl tape should be applied when both the substrate and ambient temperatures are within the manufacturer's recommended range, typically between 40°F and 100°F. Cold temperatures can reduce the tape's conformability and initial tack, while excessive heat may cause the adhesive to become too fluid for proper application.

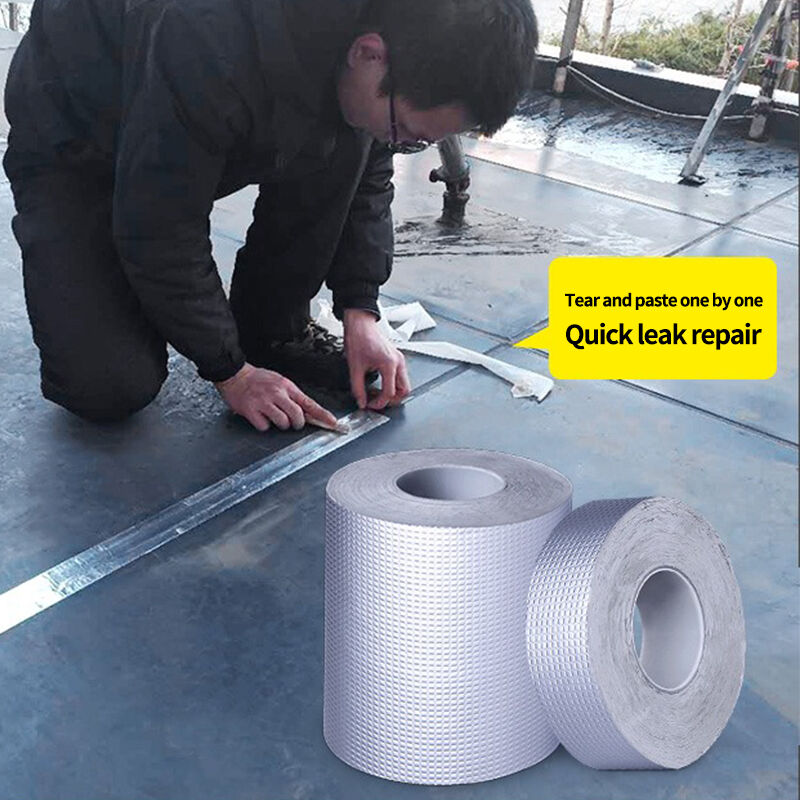

Installation Techniques and Best Practices

Proper installation of butyl tape involves systematic application techniques that ensure complete surface contact and eliminate air entrapment. The tape should be applied with firm, consistent pressure using appropriate tools such as rubber rollers or squeegees. Overlapping joints require special attention to create continuous seals without creating stress concentrations that could lead to failure.

Professional installers recognize that butyl tape performance improves over time as the adhesive system develops full bond strength through molecular interaction with the substrate. Initial positioning allows for minor adjustments, but excessive manipulation should be avoided to prevent adhesive transfer and reduced bond strength. Quality control procedures should include inspection of all sealed joints to verify complete contact and proper overlap dimensions.

Comparative Analysis with Alternative Sealing Materials

Performance Advantages Over Traditional Sealants

When compared to liquid sealants and caulks, butyl tape offers several distinct advantages in terms of application speed and consistency. Unlike liquid materials that require curing time and are subject to weather conditions during application, butyl tape provides immediate sealing capability regardless of humidity or temperature within reasonable limits. The pre-formed nature of the tape ensures consistent thickness and eliminates issues related to improper mixing or application technique.

Long-term maintenance requirements for butyl tape installations are typically lower than those for liquid sealants, which may require periodic inspection and renewal. The dimensional stability of butyl tape prevents the shrinkage and cracking commonly observed in aging caulk joints. Additionally, butyl tape can often be removed and replaced without leaving residue or damaging substrate surfaces.

Economic Considerations and Lifecycle Value

The initial cost of high-quality butyl tape may exceed that of basic sealing materials, but lifecycle analysis typically demonstrates superior value through reduced maintenance requirements and extended service life. Labor costs for butyl tape installation are often lower due to the simplified application process and immediate weather resistance that eliminates waiting periods for curing.

Failure analysis of building envelope systems frequently identifies sealant degradation as a primary cause of moisture intrusion and energy loss. The reliability of butyl tape in critical sealing applications translates to reduced risk of costly repairs and improved building performance over time. Energy savings from improved air sealing can offset material costs within the first few years of service.

Industry-Specific Applications and Requirements

Construction and Building Envelope Sealing

In commercial and residential construction, butyl tape serves critical roles in creating continuous air and moisture barriers that contribute to energy efficiency and building durability. Window and door installations rely on butyl tape to seal the interface between frames and rough openings, preventing air leakage that compromises thermal performance. The tape's conformability allows it to accommodate the dimensional variations common in construction assemblies.

Roofing applications represent a significant market for specialized butyl tape products designed to withstand extreme weather conditions and UV exposure. Metal roofing systems utilize butyl tape for sealing lap joints and penetrations, taking advantage of the material's ability to maintain adhesion to smooth metal surfaces. The tape's resistance to ponding water and thermal movement makes it suitable for low-slope roofing applications where other sealants may fail.

Automotive and Transportation Industries

The automotive industry relies on butyl tape for various sealing applications where durability and reliability are paramount. Body panel seaming, window glazing, and underhood applications benefit from the material's resistance to automotive fluids and temperature extremes. The tape's ability to dampen vibration adds acoustic benefits to structural sealing applications.

Transportation equipment manufacturers specify butyl tape for trailer and container sealing applications where cargo protection is critical. The material's resistance to road salt, diesel fuel, and cleaning chemicals ensures long-term performance in demanding service environments. Quality standards for transportation applications often exceed those for stationary installations, driving continued development of enhanced butyl tape formulations.

Quality Standards and Performance Testing

Industry Testing Protocols

Standardized testing methods for butyl tape performance include assessments of adhesion strength, water permeability, temperature cycling, and UV resistance. ASTM and other international standards provide frameworks for evaluating material properties and establishing performance criteria for specific applications. Manufacturers of premium butyl tape products typically exceed minimum standard requirements to ensure superior field performance.

Independent testing laboratories conduct long-term exposure studies that simulate years of environmental conditions in accelerated timeframes. These tests provide valuable data on material degradation rates and help predict service life under various conditions. Quality assurance programs for butyl tape manufacturing include batch testing and statistical process control to ensure consistent product performance.

Certification and Compliance Requirements

Building codes and industry standards increasingly recognize the importance of air barrier continuity and specify performance requirements for sealing materials. Butyl tape products used in critical applications must often carry third-party certifications that verify compliance with relevant standards. These certifications provide specifiers and contractors with confidence in material performance and legal protection in case of failures.

Environmental regulations addressing volatile organic compounds and material safety drive the development of low-emission butyl tape formulations. Green building programs may specify requirements for sealant materials that contribute to indoor air quality goals. Manufacturers respond to these requirements by developing products that meet or exceed environmental standards while maintaining superior sealing performance.

FAQ

How long does butyl tape maintain its sealing effectiveness

High-quality butyl tape can maintain effective sealing performance for 20-30 years or more when properly applied and not subjected to extreme conditions. The material's resistance to UV degradation, temperature cycling, and moisture exposure contributes to its exceptional longevity. Regular inspection and maintenance of sealed joints can extend service life even further by identifying and addressing minor issues before they compromise the seal.

What surface preparation is required for optimal butyl tape adhesion

Surfaces should be clean, dry, and free from oils, dust, rust, or loose particles. For porous materials like concrete or wood, primer application may be beneficial to improve adhesion and prevent adhesive migration. Metal surfaces should be degreased and may require light abrading to remove oxidation. Proper surface preparation is critical for achieving maximum bond strength and long-term durability.

Can butyl tape be applied in cold weather conditions

While butyl tape can be applied at temperatures as low as 40°F, optimal performance is achieved when both the tape and substrate are at temperatures above 50°F. Cold conditions reduce the tape's initial tack and conformability, potentially compromising adhesion. If cold weather application is necessary, the tape and substrate can be warmed prior to installation to improve application characteristics.

What makes butyl tape superior to liquid sealants for certain applications

Butyl tape offers immediate weather resistance without curing time, consistent thickness application, and superior long-term durability compared to many liquid sealants. The pre-formed nature eliminates mixing errors and application variations common with liquid materials. Additionally, butyl tape maintains flexibility over a wider temperature range and typically requires less maintenance throughout its service life, making it ideal for permanent sealing applications.

Table of Contents

- Understanding Butyl Tape Composition and Structure

- Performance Characteristics in Sealing Applications

- Application Methodologies for Maximum Effectiveness

- Comparative Analysis with Alternative Sealing Materials

- Industry-Specific Applications and Requirements

- Quality Standards and Performance Testing

- FAQ