When it comes to protecting structures from water damage, selecting the right waterproofing solution is crucial for long-term durability and performance. Among the various options available, waterproof mortar stands out as a versatile and reliable choice for both residential and commercial applications. Understanding how waterproof mortar compares to other cementitious waterproofing solutions can help you make informed decisions for your construction and renovation projects. This comprehensive comparison explores the key differences, advantages, and applications of various waterproofing methods to guide your selection process.

Understanding Waterproof Mortar Fundamentals

Composition and Basic Properties

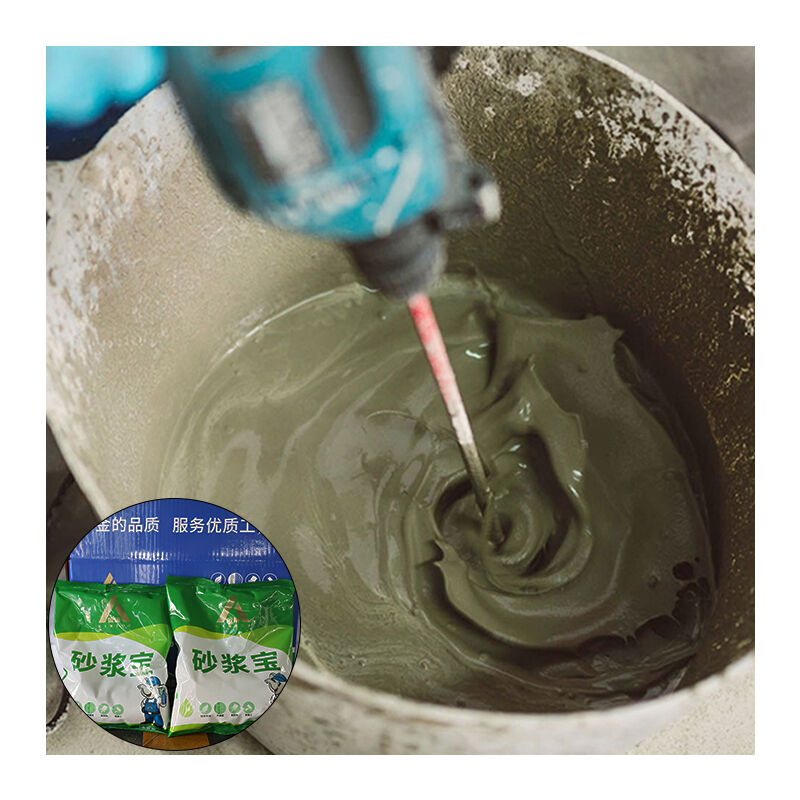

Waterproof mortar is a specially formulated mixture that combines traditional cement, sand, and aggregates with waterproofing additives and chemical admixtures. These advanced formulations create a barrier that prevents water penetration while maintaining structural integrity. The waterproofing agents in waterproof mortar typically include crystalline compounds, polymer modifiers, and hydrophobic materials that work together to reduce permeability and enhance resistance to moisture ingress.

The fundamental strength of waterproof mortar lies in its ability to bond effectively with various substrates while providing immediate waterproofing protection upon application. Unlike surface treatments that create external barriers, waterproof mortar integrates waterproofing properties directly into the structural material itself. This integration ensures consistent protection throughout the thickness of the application, making it particularly suitable for areas subjected to hydrostatic pressure or continuous moisture exposure.

Application Methods and Versatility

The application versatility of waterproof mortar makes it an attractive option for diverse construction scenarios. Professional contractors can apply waterproof mortar using traditional methods such as troweling, spraying, or pumping, depending on the specific product formulation and project requirements. This flexibility allows for efficient installation across various surface types, including concrete, masonry, and even some metal substrates with proper preparation.

Modern waterproof mortar formulations often feature extended working times and improved adhesion characteristics, enabling contractors to achieve consistent results even in challenging environmental conditions. The material's workability remains stable across different temperature ranges, making it suitable for year-round construction activities. This reliability factor contributes significantly to project scheduling efficiency and overall construction timeline management.

Comparative Analysis with Traditional Cement Waterproofing

Standard Cement-Based Systems

Traditional cement waterproofing systems rely primarily on dense concrete mixes and surface-applied cementitious coatings to achieve water resistance. While these conventional methods have proven effective in many applications, they typically require multiple application layers and extended curing periods to develop optimal waterproofing performance. Standard cement-based systems often depend on external crystalline treatments or admixtures added during mixing to enhance their waterproofing capabilities.

In contrast to these traditional approaches, waterproof mortar incorporates waterproofing technology directly into the base formulation, eliminating the need for separate waterproofing treatments. This integrated approach reduces application complexity and potential failure points that can occur when multiple systems must work together. The simplified installation process also reduces labor costs and minimizes the risk of application errors that could compromise waterproofing effectiveness.

Performance Under Pressure

When evaluating performance under hydrostatic pressure conditions, waterproof mortar demonstrates superior resistance compared to standard cement-based waterproofing systems. The specialized additives in waterproof mortar create a more uniform barrier against water penetration, even when subjected to significant pressure differentials. This enhanced pressure resistance makes it particularly valuable for below-grade applications, basement waterproofing, and infrastructure projects where groundwater pressure is a concern.

Laboratory testing consistently shows that waterproof mortar maintains its protective properties across wider pressure ranges than conventional cement waterproofing systems. This performance advantage translates to greater long-term reliability and reduced maintenance requirements for structures exposed to variable moisture conditions. The material's ability to withstand pressure cycling without degradation ensures consistent protection throughout changing seasonal conditions.

Membrane Waterproofing Versus Waterproof Mortar

Installation Complexity and Requirements

Membrane waterproofing systems, including both liquid-applied and sheet membranes, require precise surface preparation and careful attention to detail during installation. These systems often demand specialized equipment and trained applicators to achieve proper adhesion and seamless coverage. Surface irregularities, contamination, or improper primer application can significantly compromise membrane performance, leading to potential failure points and water infiltration.

Waterproof mortar offers a more forgiving installation process that accommodates minor surface imperfections and variations. The material's ability to flow and self-level during application helps create uniform coverage without the precise edge sealing and overlap requirements associated with membrane systems. This installation advantage reduces the skill level required for proper application and minimizes the risk of installation-related failures that can plague membrane waterproofing projects.

Long-Term Durability and Maintenance

While membrane waterproofing systems can provide excellent initial waterproofing performance, their long-term durability often depends on factors such as substrate movement, UV exposure, and mechanical damage. Sheet membranes are particularly susceptible to punctures, tears, and seam failures that can compromise the entire waterproofing system. Liquid-applied membranes may experience degradation from weathering or chemical exposure over time.

The inherent durability of waterproof mortar stems from its monolithic nature and chemical compatibility with concrete substrates. Unlike surface-applied membranes, waterproof mortar becomes an integral part of the structure, moving and expanding with the substrate without creating stress points or separation zones. This integration significantly reduces the likelihood of waterproofing failure due to structural movement or settling, making it particularly suitable for seismic zones or areas prone to ground movement.

Crystalline Waterproofing Technology Comparison

Activation Mechanisms and Effectiveness

Crystalline waterproofing additives work by forming insoluble crystals within concrete pores when exposed to water, creating a self-sealing barrier against further moisture penetration. While this technology can be highly effective, its performance depends on the continued presence of moisture to activate crystal formation. In dry conditions, the crystalline process may remain dormant, potentially limiting waterproofing effectiveness until water exposure occurs.

Waterproof mortar typically incorporates multiple waterproofing mechanisms beyond crystalline technology alone. These comprehensive formulations may include hydrophobic agents, polymer modifiers, and pore-blocking compounds that provide immediate waterproofing protection regardless of moisture conditions. This multi-mechanism approach ensures consistent waterproofing performance across varying environmental conditions and exposure scenarios.

Application Flexibility and Coverage

Crystalline waterproofing products are often limited to specific application methods and substrate types to achieve optimal performance. These materials may require precise mixing ratios, specific curing conditions, and controlled application environments to develop their full waterproofing potential. Deviations from recommended procedures can significantly impact the effectiveness of crystalline systems.

The formulation flexibility of waterproof mortar allows for customization to meet specific project requirements without compromising waterproofing performance. Contractors can adjust application thickness, modify working time, and adapt mixing procedures to suit site conditions while maintaining consistent waterproofing effectiveness. This adaptability makes waterproof mortar particularly valuable for complex projects with varying application requirements or challenging site conditions.

Cost Analysis and Economic Considerations

Initial Investment Comparison

When evaluating the initial cost of waterproofing solutions, waterproof mortar often presents a competitive advantage over complex membrane systems or multi-component crystalline treatments. The integrated nature of waterproof mortar eliminates the need for separate primer applications, multiple coating layers, or specialized installation equipment that can significantly increase project costs. This streamlined approach reduces both material expenses and labor requirements.

While premium waterproof mortar formulations may carry higher unit costs than standard cement products, the overall project economics often favor this solution when considering reduced installation time and simplified application procedures. The elimination of multiple-step processes and specialized contractor requirements can result in significant cost savings, particularly for larger projects where labor efficiency directly impacts profitability.

Long-Term Value and Lifecycle Costs

The durability advantages of waterproof mortar translate into favorable long-term economics through reduced maintenance requirements and extended service life. Unlike surface-applied systems that may require periodic renewal or repair, properly applied waterproof mortar provides decades of reliable waterproofing performance with minimal maintenance intervention. This longevity significantly reduces lifecycle costs compared to systems requiring regular inspection and maintenance.

Insurance and warranty considerations also favor waterproof mortar installations due to their proven track record and reduced failure rates. Many manufacturers offer extended warranties for waterproof mortar applications, providing additional economic value through risk mitigation and project protection. These warranty programs often exceed those available for membrane or coating systems, reflecting the superior reliability of integrated waterproofing approaches.

Environmental Impact and Sustainability

Manufacturing and Transportation Considerations

The environmental footprint of waterproof mortar production typically compares favorably to complex membrane manufacturing processes or specialized chemical treatments. Many waterproof mortar formulations incorporate recycled materials and industrial byproducts, reducing raw material consumption and waste generation. The local availability of basic ingredients also minimizes transportation-related environmental impacts.

Modern waterproof mortar formulations increasingly emphasize low-emission compounds and sustainable additive systems to meet evolving environmental standards. These eco-friendly formulations maintain waterproofing effectiveness while reducing volatile organic compound emissions and environmental impact during application and curing processes. This environmental consideration aligns with green building initiatives and sustainability certification requirements.

End-of-Life Considerations

The recyclability and disposal characteristics of waterproof mortar align with standard concrete recycling processes, simplifying end-of-life management compared to synthetic membrane systems. When structures reach the end of their service life, waterproof mortar can be processed through established concrete recycling channels, reducing landfill burden and supporting circular economy principles.

Unlike membrane systems that may require specialized disposal procedures for synthetic components, waterproof mortar integration with structural concrete creates a homogeneous material suitable for conventional recycling processes. This compatibility reduces demolition complexity and waste management costs while supporting sustainable construction practices throughout the entire building lifecycle.

FAQ

How long does waterproof mortar last compared to other waterproofing methods

Waterproof mortar typically provides 25-50 years of reliable waterproofing performance when properly applied, which often exceeds the service life of membrane systems that may require renewal every 10-20 years. The integrated nature of waterproof mortar ensures it ages with the structure rather than as a separate system prone to independent failure. This longevity advantage makes waterproof mortar particularly cost-effective for permanent installations where long-term reliability is prioritized over initial cost considerations.

Can waterproof mortar be applied over existing waterproofing systems

While waterproof mortar can sometimes be applied over certain existing systems with proper surface preparation, optimal performance is typically achieved through direct application to prepared substrates. Existing membrane or coating systems may interfere with proper bonding and could create potential failure points between layers. Professional evaluation of existing conditions is essential to determine compatibility and ensure proper adhesion when considering overlay applications of waterproof mortar.

What temperature conditions are required for waterproof mortar application

Most waterproof mortar formulations can be applied in temperatures ranging from 40°F to 90°F (4°C to 32°C), which is typically broader than the application range for many membrane systems. Some specialized formulations extend this range even further, enabling year-round construction activities in most climates. This temperature flexibility reduces weather-related delays and provides contractors with greater scheduling flexibility compared to more temperature-sensitive waterproofing systems.

How does waterproof mortar perform in seismic zones or areas with structural movement

Waterproof mortar demonstrates excellent performance in seismic zones due to its monolithic integration with structural substrates and ability to flex with building movement. Unlike rigid membrane systems that may crack or separate during seismic events, waterproof mortar moves as part of the structure itself. Many formulations include polymer modifiers that enhance flexibility while maintaining waterproofing effectiveness, making them particularly suitable for earthquake-prone regions where structural movement is a concern.

Table of Contents

- Understanding Waterproof Mortar Fundamentals

- Comparative Analysis with Traditional Cement Waterproofing

- Membrane Waterproofing Versus Waterproof Mortar

- Crystalline Waterproofing Technology Comparison

- Cost Analysis and Economic Considerations

- Environmental Impact and Sustainability

-

FAQ

- How long does waterproof mortar last compared to other waterproofing methods

- Can waterproof mortar be applied over existing waterproofing systems

- What temperature conditions are required for waterproof mortar application

- How does waterproof mortar perform in seismic zones or areas with structural movement