rapid road repair

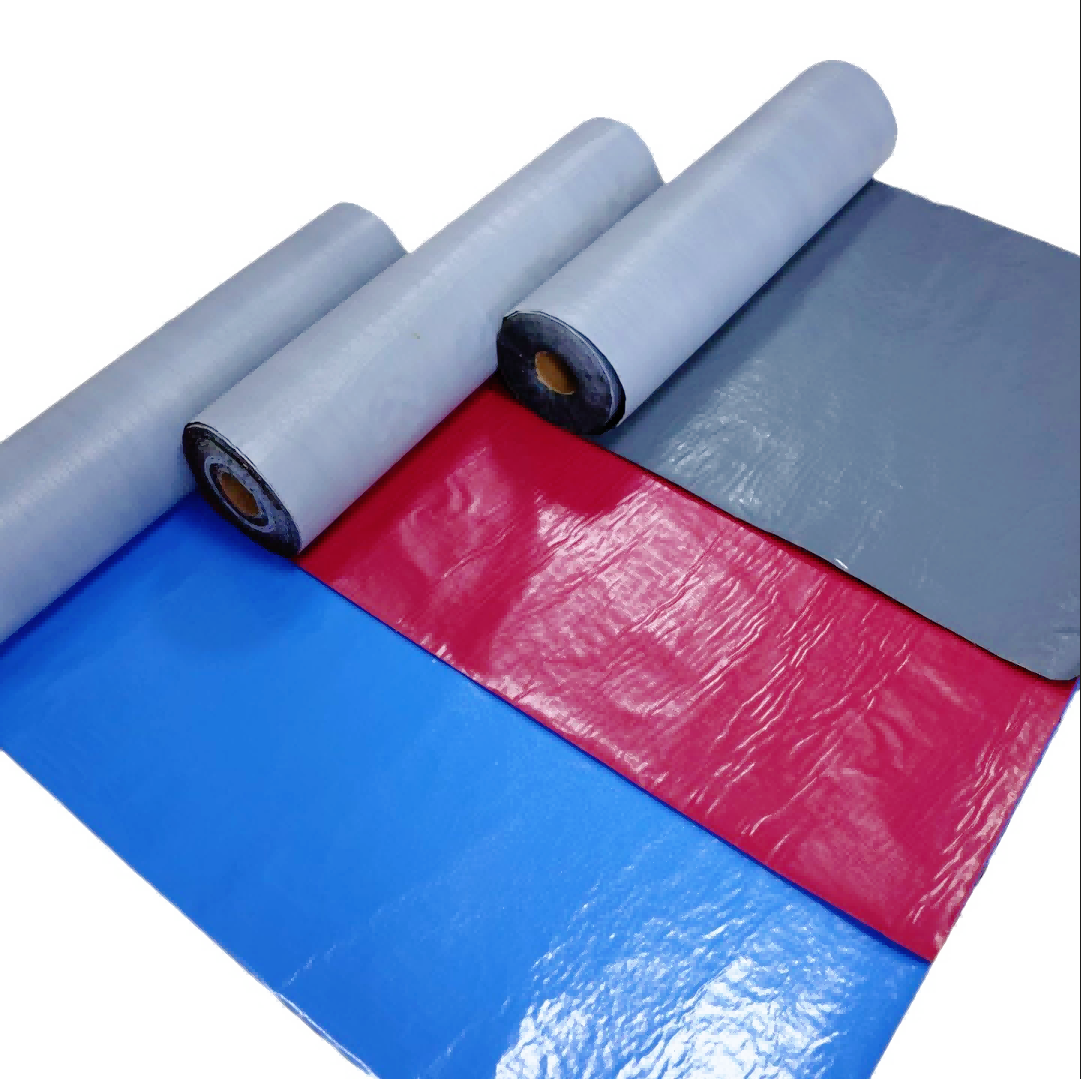

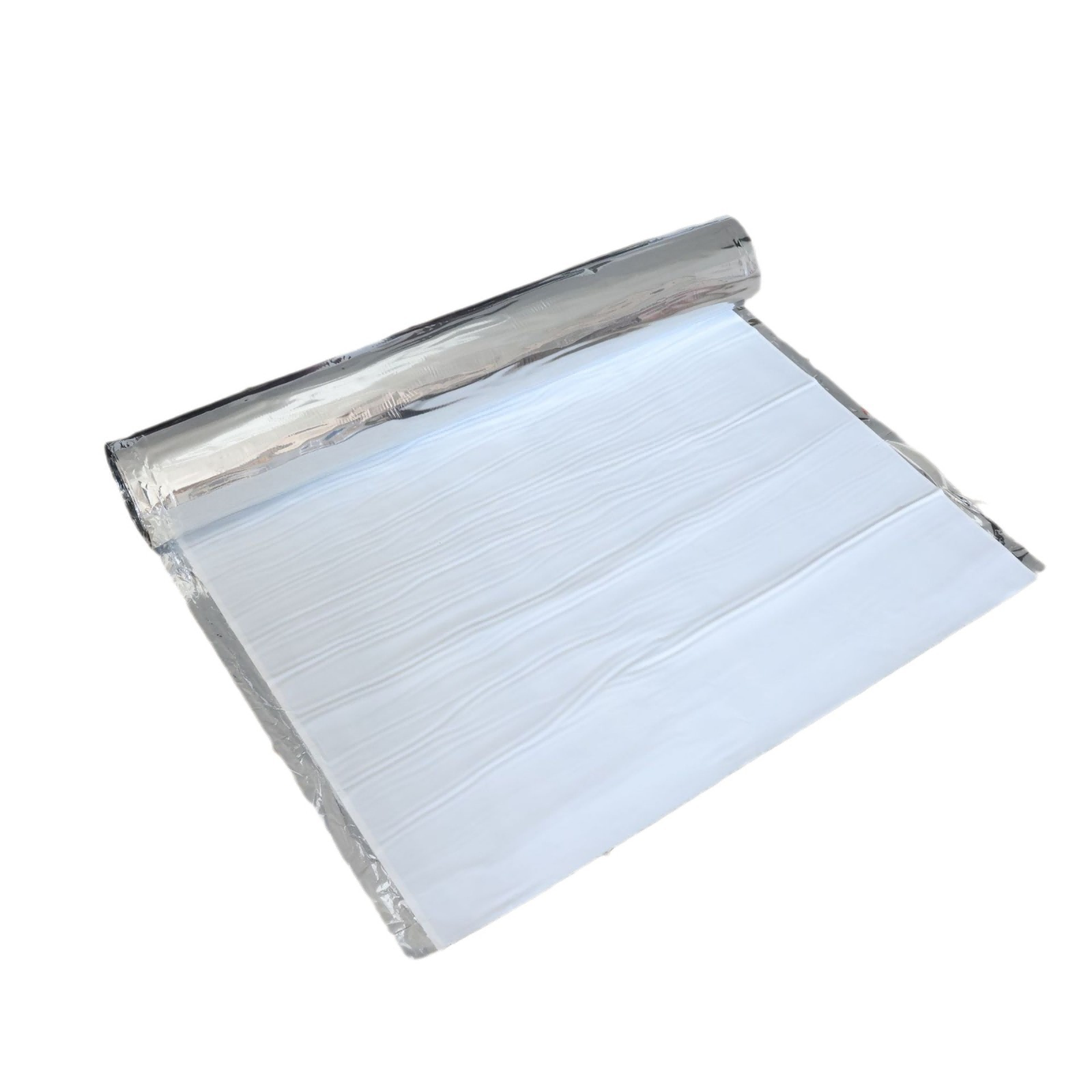

Rapid road repair represents a cutting-edge solution in modern infrastructure maintenance, designed to address pavement deterioration quickly and effectively. This innovative system combines advanced materials technology with efficient application methods to deliver swift, durable repairs for various road surface issues. The technology utilizes specially formulated quick-setting compounds that can withstand heavy traffic loads within hours of application, significantly reducing road closure times. The system encompasses a comprehensive approach, from initial surface preparation to final curing, ensuring optimal bonding and longevity. It's particularly effective for repairing potholes, cracks, and surface deterioration in both asphalt and concrete pavements. The application process involves specialized equipment that ensures precise material mixing and placement, maintaining consistency across repairs. Advanced polymer modifications in the repair materials provide enhanced durability and weather resistance, making repairs more resilient to environmental stresses. This solution has proven especially valuable in urban environments where traditional lengthy repair processes cause significant disruption to traffic flow. The system's versatility allows for applications in varying weather conditions, making it practical for emergency repairs throughout the year.