Introduction

Modern construction and maintenance professionals face increasing challenges when addressing roof and ceiling water intrusion issues. Traditional repair methods often provide temporary solutions that fail to withstand environmental stresses and long-term exposure. The Single-component Aspartic Resin Jointing Material for Roof Ceiling Leakage Repair and Waterproof Coating represents a breakthrough in advanced waterproofing technology, offering superior performance characteristics that exceed conventional repair materials. This innovative formulation combines the durability of aspartic ester chemistry with the convenience of single-component application, eliminating mixing requirements while delivering exceptional adhesion and weather resistance.

Professional contractors and facility managers worldwide increasingly recognize the importance of reliable waterproofing solutions that provide long-lasting protection against moisture infiltration. This specialized jointing material addresses critical performance gaps found in traditional sealants and coatings, delivering enhanced flexibility, UV stability, and chemical resistance. The formulation demonstrates exceptional compatibility with diverse substrate materials commonly encountered in roofing applications, making it an ideal choice for comprehensive waterproofing projects across residential, commercial, and industrial sectors.

Product Overview

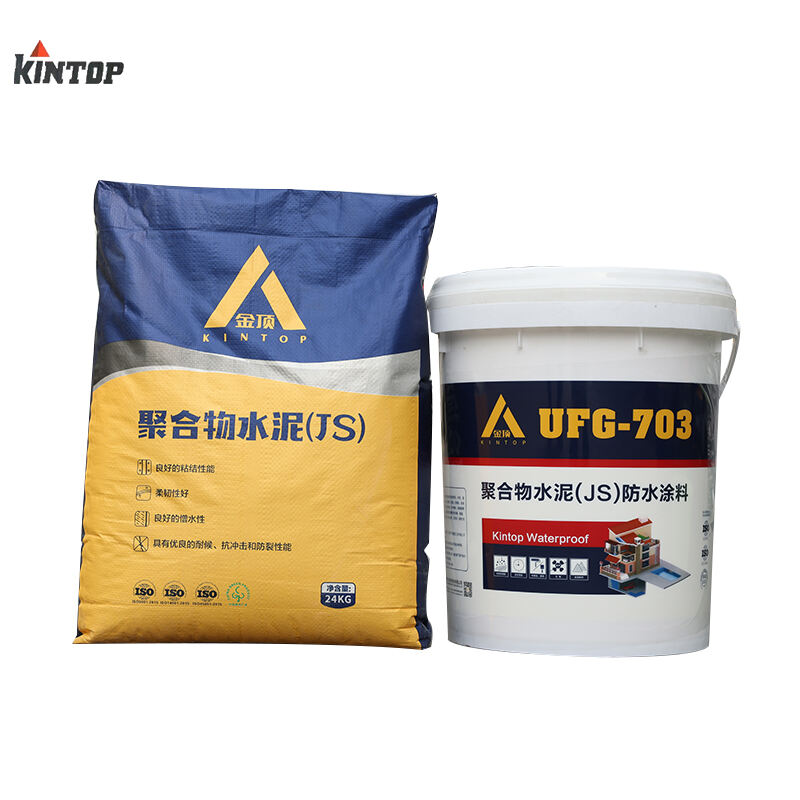

The Single-component Aspartic Resin Jointing Material for Roof Ceiling Leakage Repair and Waterproof Coating utilizes advanced aspartic ester technology to deliver superior waterproofing performance in a convenient, ready-to-use formulation. Unlike traditional two-component systems that require precise mixing ratios and limited working times, this innovative material offers extended pot life and simplified application procedures that reduce installation complexity and potential application errors.

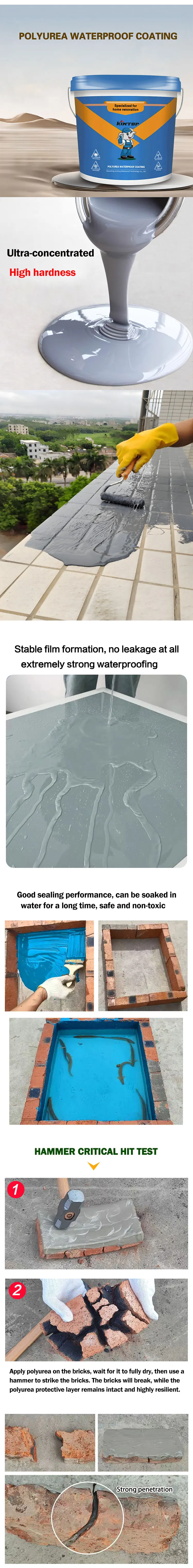

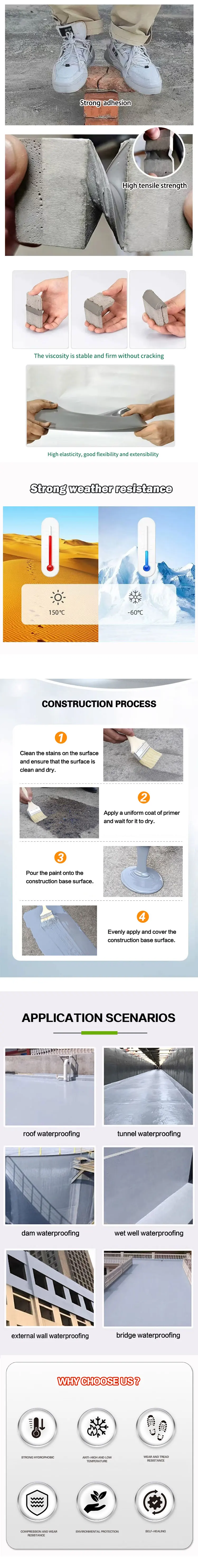

This specialized waterproofing solution exhibits exceptional adhesion properties on various substrate materials including concrete, metal, wood, and existing roofing membranes. The aspartic resin chemistry provides outstanding resistance to thermal cycling, UV degradation, and chemical exposure while maintaining flexibility across wide temperature ranges. The material cures to form a seamless, monolithic membrane that effectively bridges gaps, seals joints, and provides comprehensive leak repair capabilities.

Professional applicators appreciate the material's excellent flow characteristics and self-leveling properties, which facilitate uniform coverage and eliminate common application issues associated with conventional repair compounds. The formulation demonstrates rapid initial set properties while allowing sufficient working time for proper application techniques, making it suitable for both emergency repairs and planned maintenance projects.

Features & Benefits

Advanced Chemical Resistance

The aspartic resin foundation provides exceptional resistance to chemical exposure, including acids, alkalis, oils, and common industrial solvents. This chemical stability ensures long-term performance in challenging environments where traditional materials may deteriorate rapidly. The cross-linked polymer structure maintains its integrity even under continuous exposure to harsh chemicals, making it suitable for industrial roofing applications where chemical resistance is paramount.

Superior Weather Resistance

Engineered for extreme weather conditions, this Single-component Aspartic Resin Jointing Material for Roof Ceiling Leakage Repair and Waterproof Coating demonstrates outstanding resistance to UV radiation, temperature fluctuations, and moisture exposure. The material maintains its physical properties across wide temperature ranges, preventing cracking and deterioration commonly observed with conventional sealants. This weather stability translates to reduced maintenance requirements and extended service life in outdoor applications.

Exceptional Adhesion Properties

The formulation exhibits superior adhesion to diverse substrate materials without requiring primers in most applications. This excellent bonding capability ensures reliable performance on concrete, masonry, metal, wood, and existing roofing membranes. The strong adhesive bond prevents water infiltration at interface areas, providing comprehensive leak protection that addresses both surface damage and joint failures.

Flexible Membrane Formation

Upon curing, the material forms a highly flexible, elastomeric membrane that accommodates structural movement and thermal expansion without compromising waterproof integrity. This flexibility prevents stress cracking and maintains seal effectiveness even under dynamic loading conditions commonly encountered in building applications. The elastomeric properties ensure long-term performance in areas subject to settlement, vibration, or thermal cycling.

Applications & Use Cases

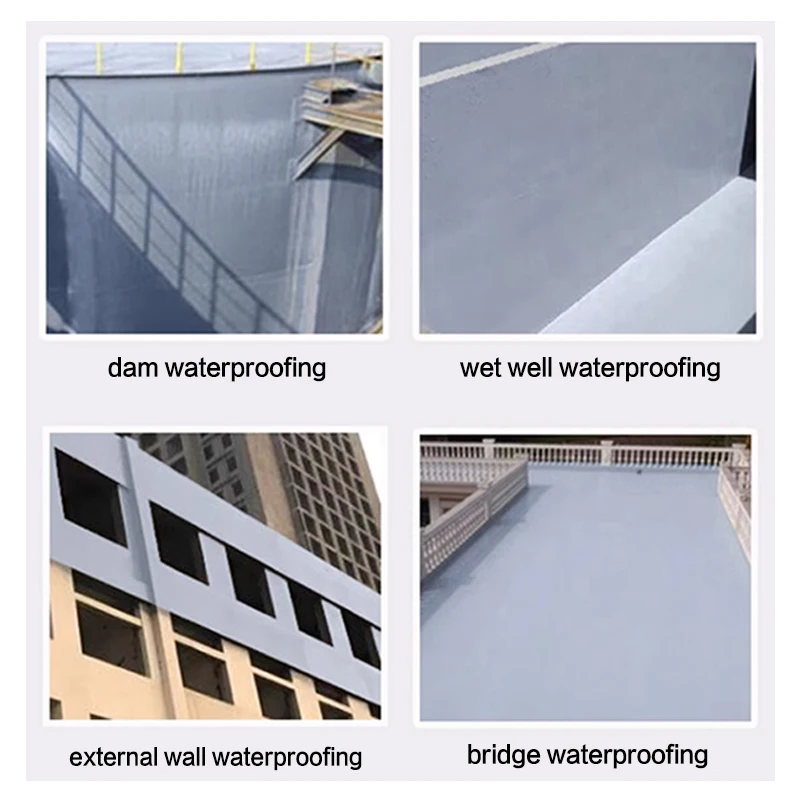

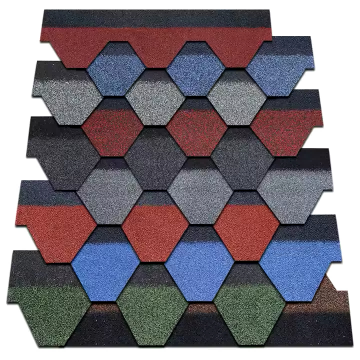

The versatility of this Single-component Aspartic Resin Jointing Material for Roof Ceiling Leakage Repair and Waterproof Coating makes it suitable for numerous roofing and waterproofing applications across diverse market segments. Commercial building maintenance teams utilize this material for emergency leak repairs, planned maintenance projects, and comprehensive roof restoration programs. The material's excellent adhesion and flexibility make it particularly effective for addressing common failure points such as roof penetrations, expansion joints, and membrane transitions.

Industrial facilities benefit from the material's chemical resistance and durability when addressing waterproofing challenges in manufacturing environments. The formulation performs exceptionally well in areas exposed to industrial chemicals, temperature extremes, and mechanical stress. Food processing facilities, chemical plants, and manufacturing operations rely on this advanced waterproofing solution to maintain facility integrity while meeting strict hygiene and safety requirements.

Residential applications include flat roof repairs, basement waterproofing, and exterior wall sealing projects. Contractors appreciate the material's ease of application and reliable performance when addressing homeowner waterproofing concerns. The single-component formulation eliminates mixing errors and reduces application complexity, making it ideal for both professional contractors and experienced maintenance personnel.

Infrastructure projects leverage the material's longevity and performance characteristics for bridge deck waterproofing, parking structure protection, and transportation facility maintenance. The material's ability to withstand traffic loading, de-icing chemicals, and harsh environmental conditions makes it suitable for critical infrastructure applications where performance reliability is essential.

Quality Control & Compliance

Manufacturing excellence ensures consistent product quality through rigorous testing protocols and quality assurance procedures implemented throughout the production process. Each batch undergoes comprehensive laboratory analysis to verify physical properties, chemical composition, and performance characteristics before release. Advanced testing methodologies evaluate adhesion strength, flexibility retention, weather resistance, and chemical compatibility to guarantee consistent performance across all production runs.

The Single-component Aspartic Resin Jointing Material for Roof Ceiling Leakage Repair and Waterproof Coating meets or exceeds relevant industry standards for waterproofing materials and roofing applications. Compliance with international quality standards ensures product acceptance across global markets while providing specifiers and contractors with confidence in material performance. Regular third-party testing validates ongoing compliance with applicable standards and regulations.

Environmental considerations are integrated throughout the manufacturing process, with formulations designed to minimize volatile organic compound emissions while maintaining superior performance characteristics. The material supports green building initiatives and sustainable construction practices through its durability, longevity, and reduced maintenance requirements. Life-cycle assessments demonstrate favorable environmental impact compared to conventional waterproofing materials requiring frequent replacement or maintenance.

Customization & Branding Options

Recognizing the diverse needs of global markets, comprehensive customization capabilities accommodate specific regional requirements and application preferences. Formulation modifications address local climate conditions, substrate compatibility requirements, and performance specifications unique to different geographic markets. Technical teams collaborate with distributors and contractors to develop optimized solutions that meet local standards and application conditions.

Private label opportunities enable distributors and contractors to build brand recognition while offering proven waterproofing technology to their customers. Customized packaging options support brand differentiation strategies and market positioning requirements across different regions and customer segments. Technical documentation, application guides, and training materials are available in multiple languages to support international market development initiatives.

Color matching capabilities allow the Single-component Aspartic Resin Jointing Material for Roof Ceiling Leakage Repair and Waterproof Coating to blend seamlessly with existing roof membranes and architectural elements. Custom color formulations maintain all performance characteristics while providing aesthetic compatibility with diverse building designs and color schemes. This flexibility supports both functional and aesthetic requirements in visible waterproofing applications.

Packaging & Logistics Support

Efficient packaging solutions optimize storage requirements, handling convenience, and application efficiency while maintaining product integrity throughout the supply chain. Container designs facilitate easy dispensing and minimize waste, supporting cost-effective project execution and material utilization. Packaging materials provide excellent barrier properties to protect against moisture intrusion and contamination during storage and transportation.

Global logistics capabilities ensure reliable product availability across international markets through strategic distribution partnerships and regional warehousing facilities. Supply chain optimization reduces lead times and transportation costs while maintaining consistent product quality and availability. Temperature-controlled shipping protocols protect product integrity during transportation in extreme climate conditions.

Technical support documentation accompanies each shipment, providing application guidelines, safety information, and troubleshooting resources in appropriate languages for target markets. Comprehensive labeling ensures compliance with local regulations while providing clear product identification and application instructions. Digital resources including application videos and technical datasheets support successful project execution and customer satisfaction.

Why Choose Us

Our organization brings decades of experience in advanced polymer chemistry and waterproofing technology to deliver innovative solutions that exceed customer expectations across global markets. International market presence spans multiple continents, with established partnerships supporting diverse industries and applications. This extensive experience enables deep understanding of regional requirements and application challenges, resulting in optimized product formulations and superior customer support.

As a recognized metal packaging supplier and custom tin box supplier, our expertise extends beyond waterproofing materials to encompass comprehensive packaging solutions that protect and preserve product integrity. Our multi-industry expertise enables innovative approaches to product development and customer service that leverage best practices across different market segments. OEM tin packaging solutions developed through this experience ensure optimal product protection and customer convenience.

Research and development capabilities drive continuous innovation in aspartic resin technology and waterproofing applications. Advanced laboratory facilities enable thorough product testing and validation while supporting custom formulation development for specific customer requirements. Technical teams collaborate with customers worldwide to address unique challenges and develop optimized solutions that deliver exceptional value and performance reliability.

Global collaboration networks facilitate knowledge sharing and technology transfer that benefit customers through improved products and expanded application capabilities. Metal packaging manufacturer partnerships support comprehensive supply chain integration and streamlined logistics that reduce costs and improve service levels. This collaborative approach ensures customers receive the most advanced waterproofing technology supported by world-class service and technical expertise.

Conclusion

The Single-component Aspartic Resin Jointing Material for Roof Ceiling Leakage Repair and Waterproof Coating represents a significant advancement in waterproofing technology, combining convenience, performance, and reliability in a single solution. Its superior adhesion properties, chemical resistance, and weather durability make it an ideal choice for diverse roofing and waterproofing applications across residential, commercial, and industrial sectors. The material's flexibility and ease of application reduce installation complexity while delivering long-term protection against water infiltration and structural damage. Professional contractors and facility managers benefit from reduced maintenance requirements, extended service life, and reliable performance that exceeds traditional waterproofing materials. This innovative aspartic resin formulation continues to set new standards for waterproofing excellence, supporting sustainable building practices and cost-effective facility maintenance across global markets.