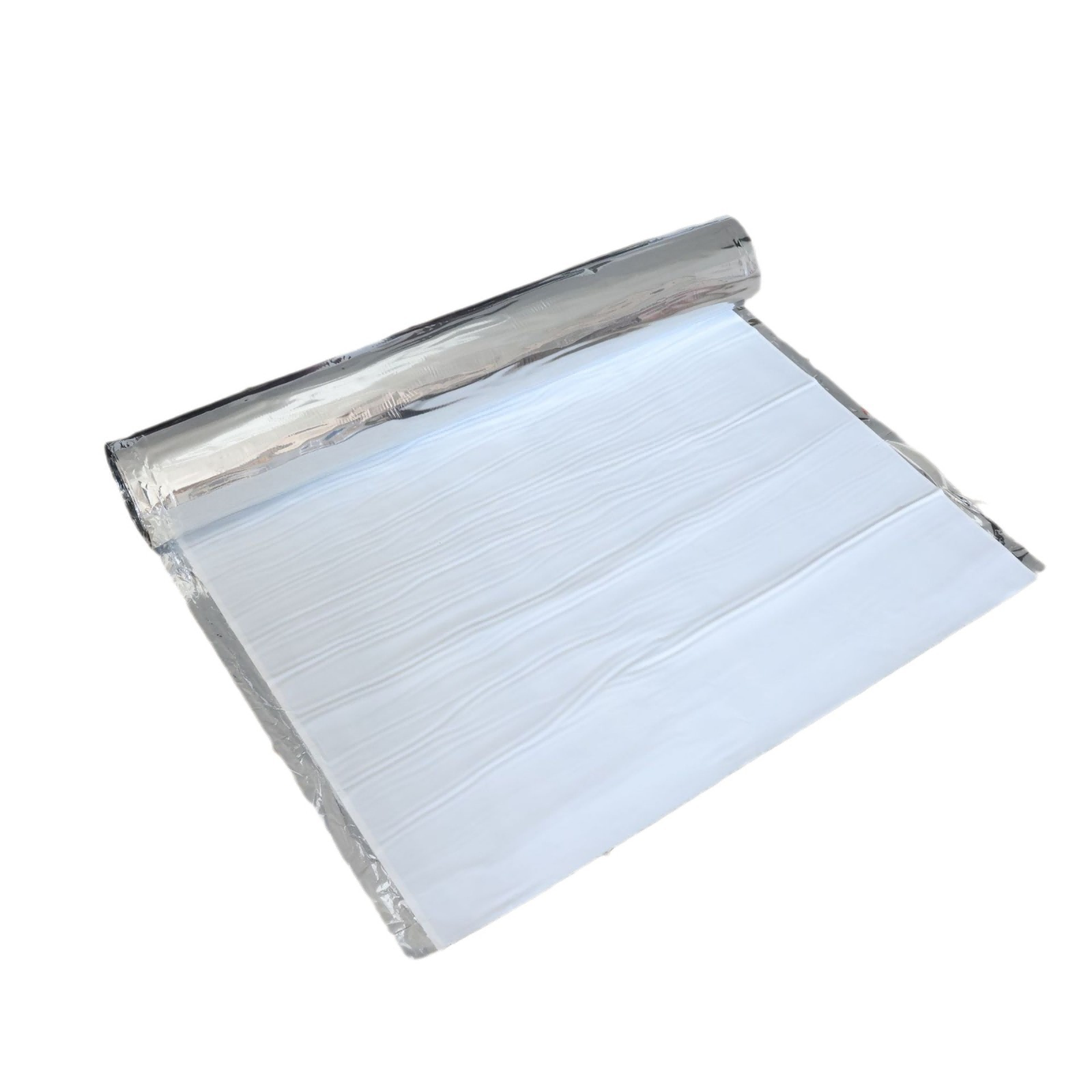

hot bitumen waterproofing

Hot bitumen waterproofing is a time-tested method for protecting structures against water infiltration. This robust waterproofing system involves the application of heated bitumen, a viscous and highly adhesive material derived from petroleum processing. The process begins with thoroughly cleaning and preparing the substrate surface, followed by heating the bitumen to temperatures ranging between 180-220°C to achieve optimal viscosity. The molten bitumen is then systematically applied to the surface, creating a seamless, impermeable membrane that bonds firmly with the substrate. This technique is particularly effective for flat roofs, foundations, and underground structures where water resistance is crucial. The application process typically involves multiple layers, including reinforcement materials such as fiberglass or polyester mats, which enhance the system's durability and tensile strength. The hot bitumen method creates a monolithic layer that effectively seals joints, seams, and penetrations, providing comprehensive protection against water ingress. Its superior adhesion properties ensure long-term performance, while its self-healing characteristics help maintain integrity even under minor structural movements. This waterproofing solution is widely used in commercial, industrial, and civil engineering projects where reliability and longevity are paramount considerations.