daxistina poliûrê la ciment

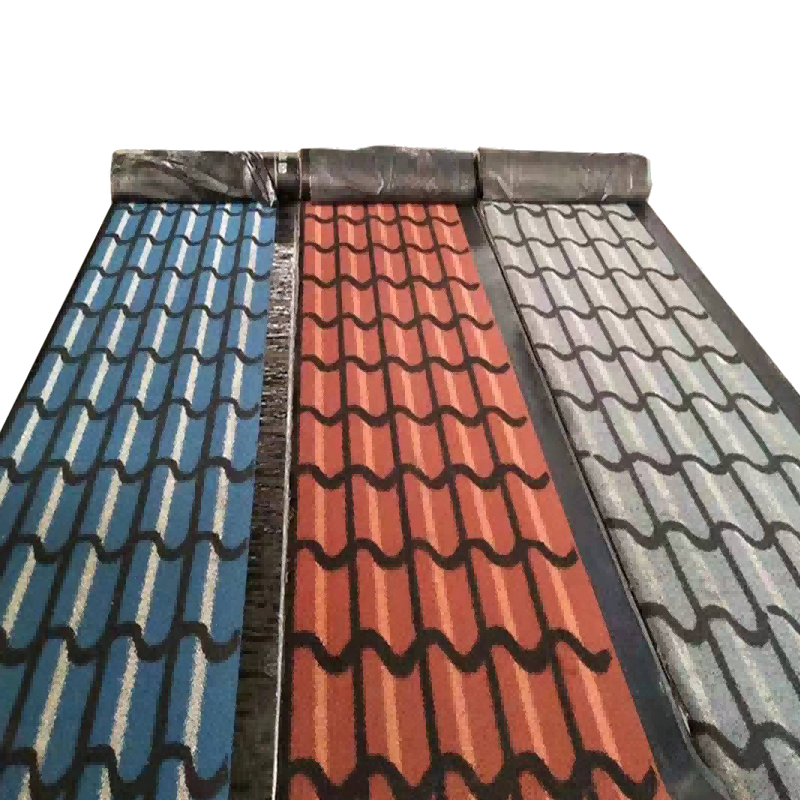

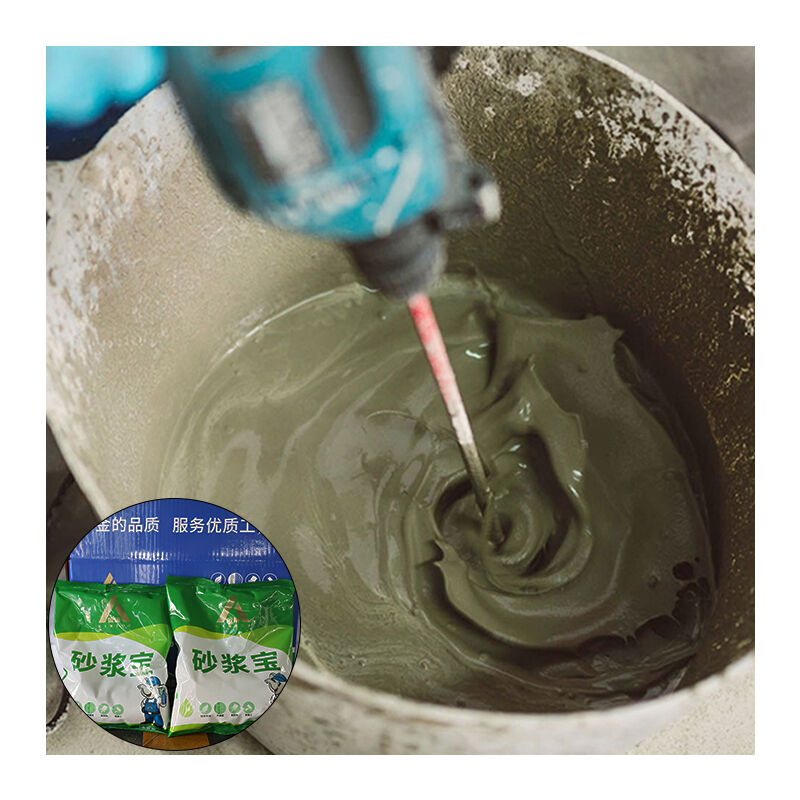

Koçîna poliurea ji bo çiment re berhevî ya nû ên bi teçnikayek serbixeyî ye ku di pêşdîtinê de pirsgirêkên dawî ya çimentê ve hatine rast kirin. Ev sisteme koçîna nûnavî tê jî hilbijartin li ser du komponent, 100% bingehaneke, û bi destpêkirina spray-ê re hatine were nekinî serbest. Li derveja vê koçîna, mem lehengî ya piwîstî di zimanên kurt de hate alîkirin, ku vê yewarê di vê hejmarê de wekî herî tiştên koçînên tradisional bike. Koçîna xwe pelanekî ya nehatiye were çêkirin ku ji aliyê derxwendî, tevahî yên kimyaî û şoreşên fîzîkî di navbera çimentê de din were pargirtin. Strukturaya molekulanî ya vî ya tersîbî elastîsîteya gewtirîyê were daykirin, ku ev ewle bike da ku ji wê heyî di navbera girokê de were çêkirin û bicîhîna pelê were qebûl bikin paşî ta pirsgirêka xwe nehatiyan nekare. Koçîna herêmî ya gewtirîyê yên tevahî yên UV, guharekên tempratûr û stresekan mekanîkî were nîşan dandin, ku ev vê destpêkê ji bo karvanên sasî û derveyî were girîngkirin. Sistemên koçîna poliurea li ser herî tişt û derveyî di navbera sektorên rêza, wekî zevî ya malpana, binavên parkir, serhildana nexwazî û binavên comerse ya komerse were bikar anîn. Versatîlîtya vê koçîna li ser karvanên decora diyarî were çêkirin, ku ev li ser riya rang û tekstûrên wergerîn dikarin biguhezhkirin da ku reqamên estetîkî yên spesîfyîk were pêkirdin tenmînî ta pirsgirêka xwe nehatiyan nekare.