지하 방수용 멤브레인이 상업용 건물을 어떻게 보호할 수 있는가?

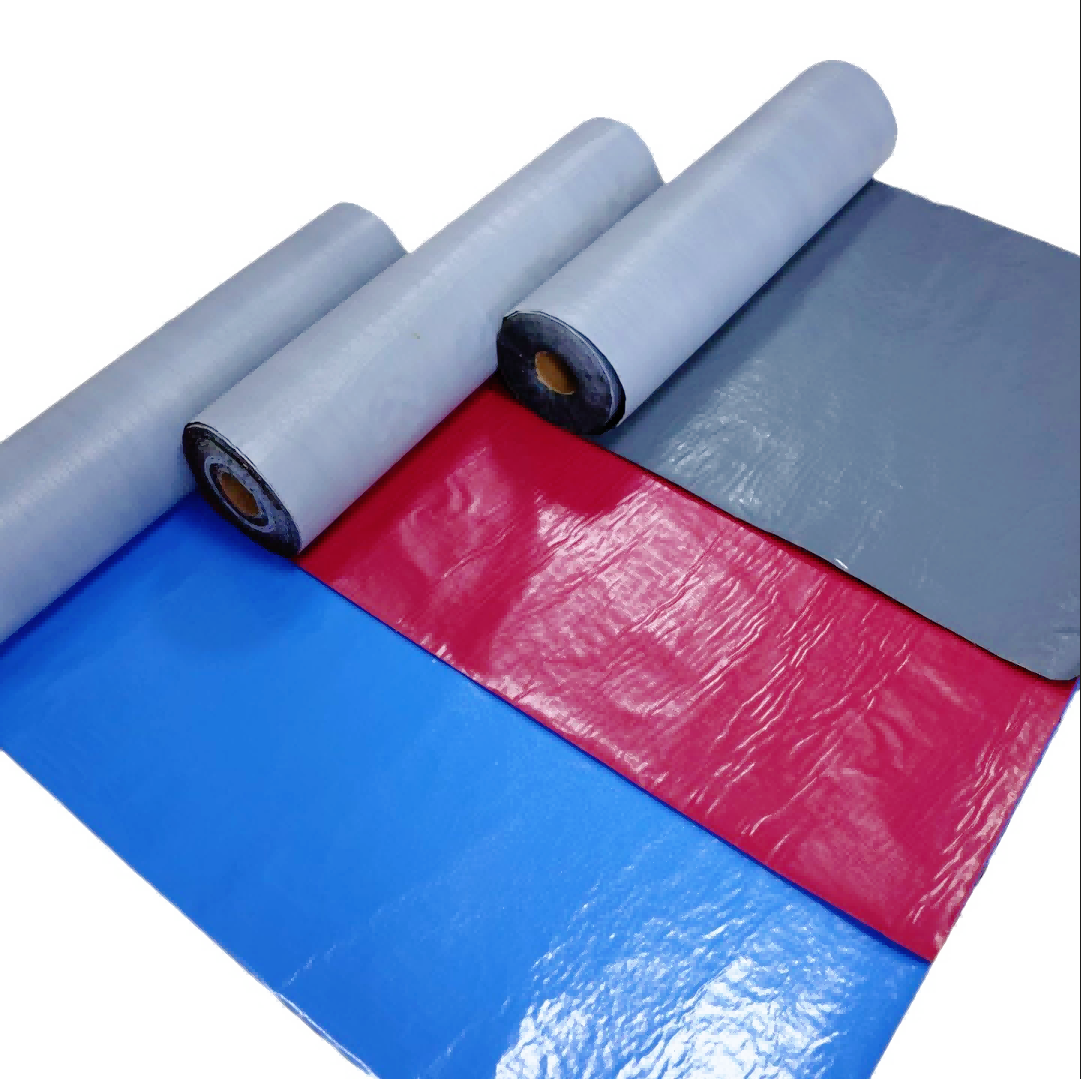

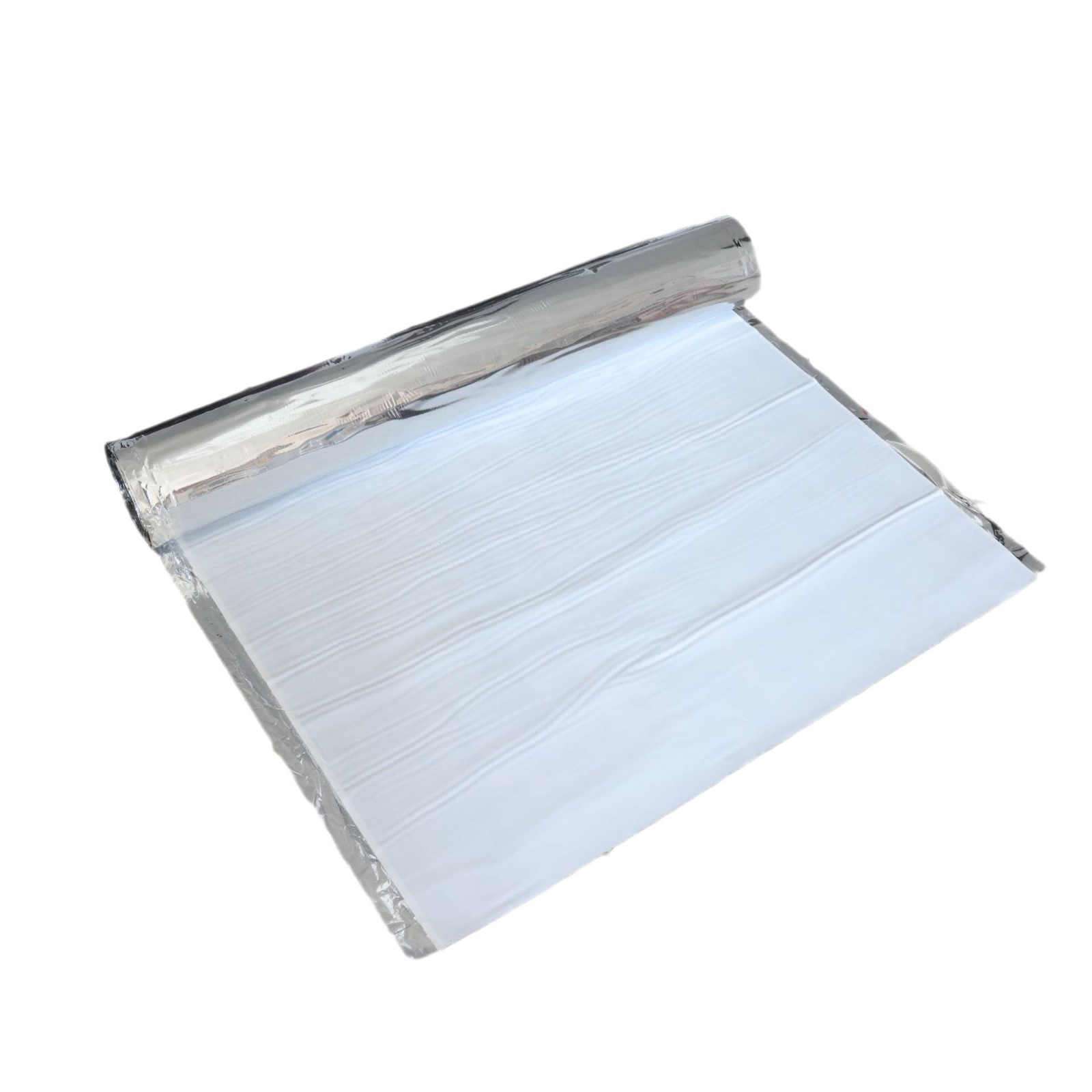

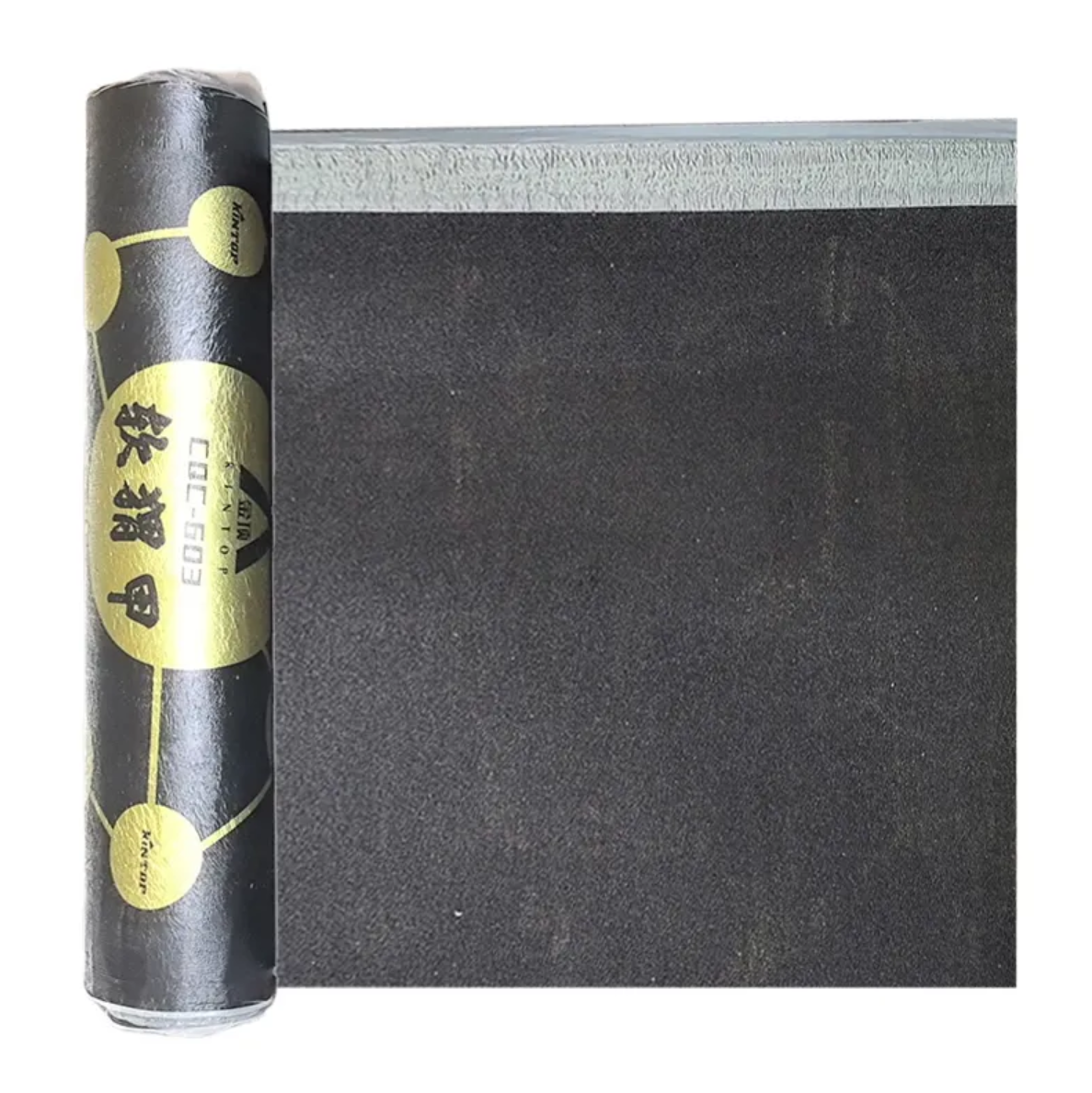

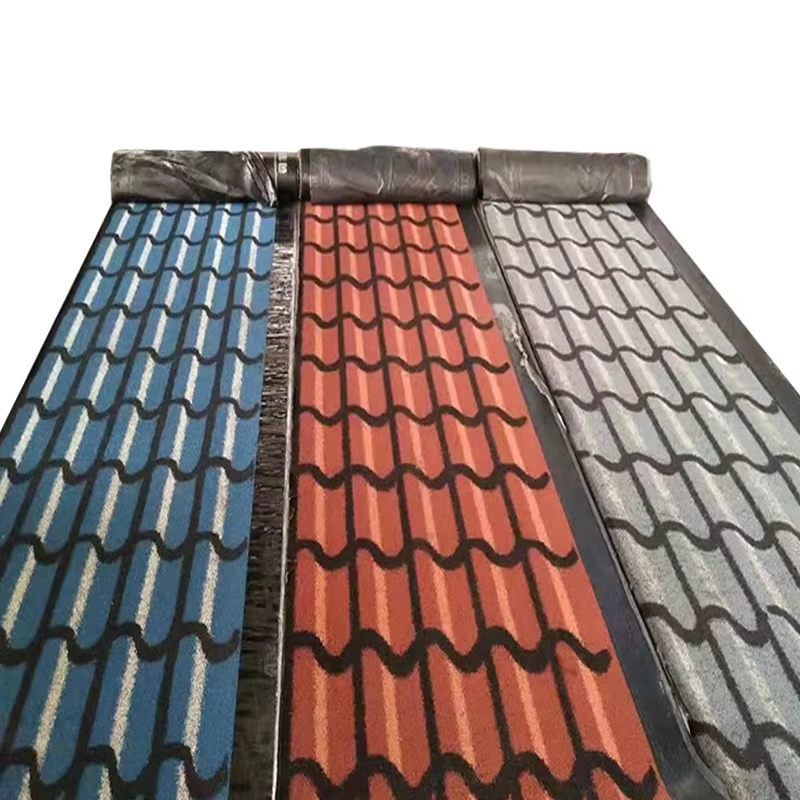

상업용 건설에서 방수 솔루션의 핵심 역할 이해 상업용 건물은 특히 지하 구조부위에서 물 피해로부터 강력한 보호가 필요한 중요한 투자 자산이다. 지하 방수용 멤브레인은 지하수, 비, 눈 녹은 물 등 외부 수원으로부터 건물을 보호하여 습기 침투, 곰팡이 발생, 구조적 손상 등을 방지한다. 이는 건물의 수명을 연장하고 유지보수 비용을 절감하며, 실내 공기질과 거주자의 안전을 보장하는 데 기여한다.

더 보기